Main Reason for Drying Veneer Introduction

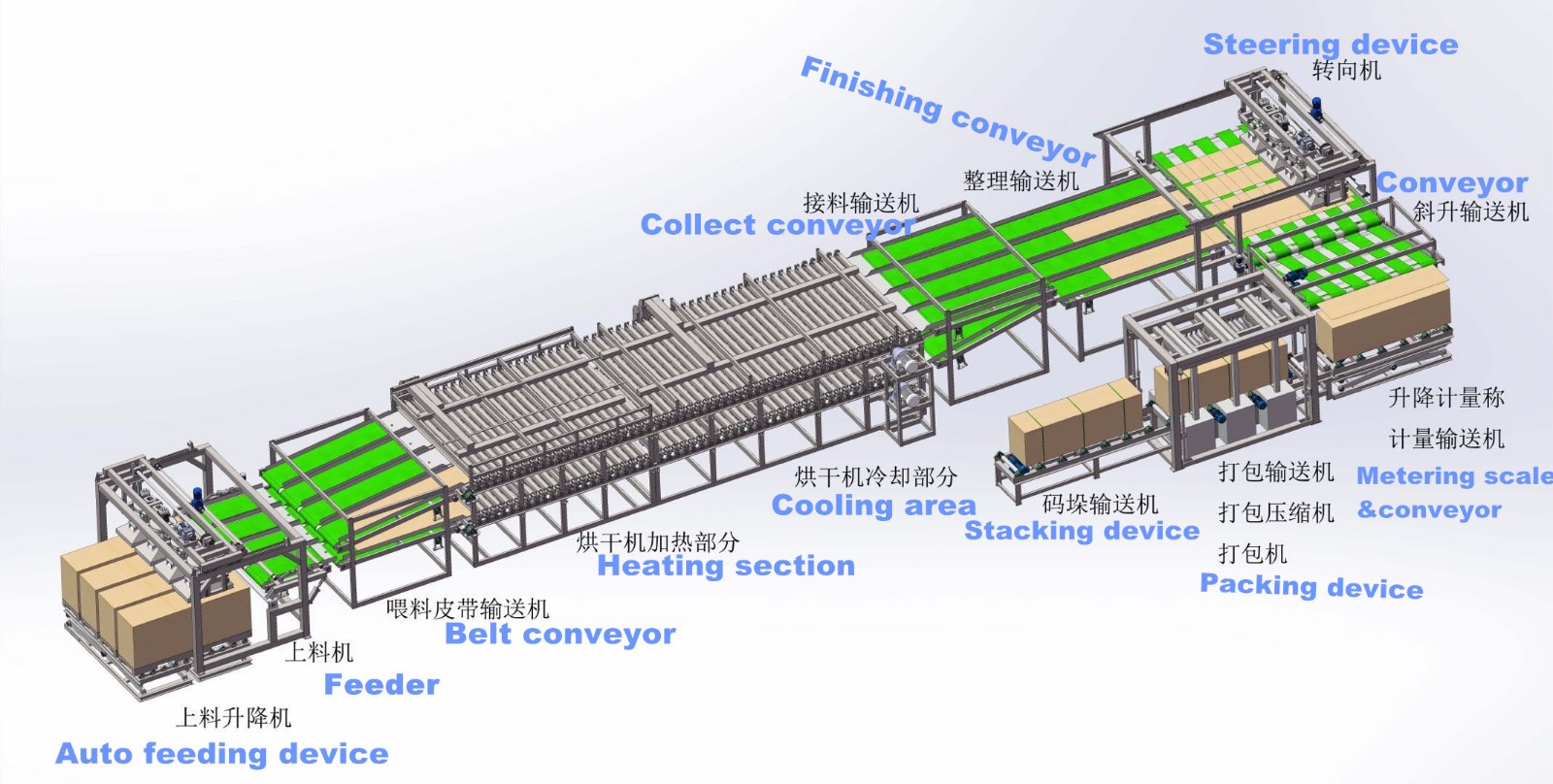

The main reason for the drying veneer is to remove excess moisture so that the veneers are prepared for adhesive application and product manufacture. Drying soon after clipping is preferred, to prevent mould, veneer distortion(e.g. buckling) and other degradation. Practical objectives are to dry at low cost, with short drying time, and to achieve appropriate quality. Veneer drying approaches have evolved over time. The simplest and lowest cost approach is to air-dry veneers, however, this gives little control over drying time and quality. There are various types of mechanical drying systems, with the most common in larger commercial operations being the jet-box conveyer-type dryer. With this system, veneers are fed along a conveyor system into the dryer and passed through a series of chambers where hot air is blasted across the veneers. Temperature and conveyor speeds are adjusted to ensure the veneer exits the dryer with the appropriate moisture content and suitable quality.

Main Reason for Drying Veneer Main Pictures

Fast dehydration capability: Shine's veneer dryers usually use efficient heating methods such as hot air circulation, steam heating or infrared radiation, which can dry the veneer in a short time, greatly shortening the drying time.

Continuous production: Large veneer dryers are mostly assembly line designs, which can achieve continuous feeding, drying and discharging of veneers, avoiding the discontinuity of traditional natural drying, suitable for large-scale production, and improving enterprise production capacity.

Technical Parameter for Main Reason for Drying Veneer Machine

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kw) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

Air cooling fan power(kw) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kw) | 132 | 147 | 158 | 169 | 180 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

For investors interested in investing in the single board production industry, visiting equipment suppliers' factories on-site is not an optional step, but a key step related to the scientificity of investment decisions, risk controllability, and long-term stability of returns.

1. Eliminate information gaps and verify the true strength of the equipment

2. Evaluate production matching and reduce investment mismatch risk

5. Obtain industry information and optimize investment strategies

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd