In the fast-paced world of panel manufacturing—encompassing wood, metal, composite, and engineered materials—robotic arms have emerged as indispensable tools for achieving unmatched precision, efficiency, and scalability. By automating critical processes such as material handling, loading/unloading, and palletizing, these versatile machines eliminate bottlenecks, reduce labor costs, and elevate product quality. This article explores how robotic arms, coupled with advanced technologies like vacuum grippers and vision systems, are transforming panel production across industries.

1. Material Handling & Loading/Unloading

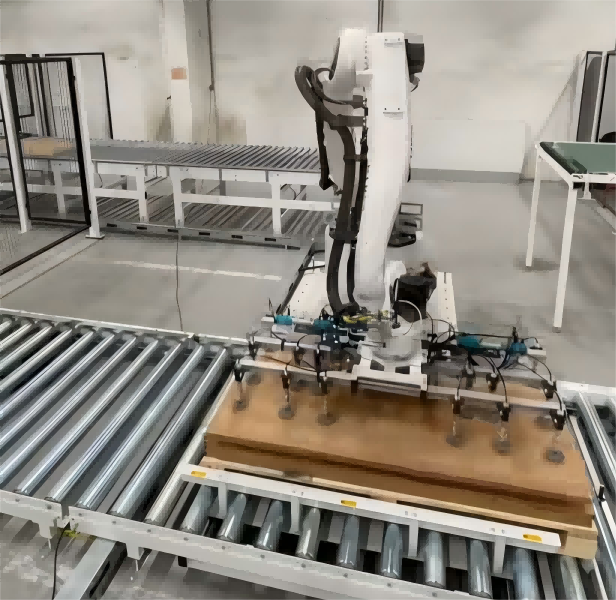

Robotic arms excel in transporting raw materials (e.g., logs, plywood sheets) and finished panels between production stages. Equipped with vacuum suction cups or mechanical grippers, they handle heavy, cumbersome panels with ease, minimizing human error and physical strain. For example:

In plywood manufacturing, robotic arms load logs onto debarking machines and transfer veneer sheets between drying, cutting, and gluing stations.

In furniture production, they precisely position particleboard panels for CNC machining, ensuring alignment accuracy within ±0.1mm.

2. Stacking & Palletizing

Automated palletizing is a game-changer for warehouses and distribution centers. Robotic arms stack finished panels (e.g., MDF boards, OSB panels) into neat, secure pallets tailored to shipping requirements:

Dynamic stacking patterns: Adjusts layer configurations based on panel dimensions and weight distribution.

Cycle times: Achieves speeds of 120–180 cycles per hour, rivaling manual labor while eliminating fatigue-related errors.

Space optimization: Maximizes pallet density through intelligent algorithms, reducing transportation costs.

3. Quality Inspection & Defect Detection

When integrated with machine vision systems, robotic arms become powerful quality control agents:

Real-time scanning: High-resolution cameras and LiDAR sensors identify surface defects (e.g., knots, cracks, warping) during production.

Automated sorting: Defective panels are segregated from batches, ensuring only compliant products proceed downstream.

Edge trimming: Collaborative robots (cobots) guide panels through trimming stations, maintaining consistent dimensions.

a. Versatility in End-of-Arm Tooling

Vacuum grippers: Ideal for smooth, flat panels (e.g., veneer, laminate), creating airtight seals for secure lifting.

Mechanical grippers: Offer adjustable force control for fragile materials (e.g., thin MDF) or irregular shapes.

Hybrid systems: Combine suction and mechanical grips for hybrid applications (e.g., lifting plywood while aligning edges).

b. Adaptability to Harsh Environments

Heat resistance: Operates safely near kilns, ovens, or steam treatment chambers (common in veneer drying).

Dust suppression: Enclosed designs and IP-rated components withstand sawdust, resin particles, and moisture.

Chemical resistance: Safe for environments exposed to adhesives, coatings, or finishing chemicals.

c. Integration with Industry 4.0 Technologies

IoT connectivity: Real-time data exchange with MES/ERP systems for predictive maintenance and workflow optimization.

AI-driven analytics: Predicts tool wear, identifies inefficiencies, and suggests process improvements.

Collaborative workflows: Cobots work alongside humans in shared spaces, enhancing flexibility for custom orders.

As panel production evolves, robotic arms are poised to unlock new frontiers:

Swarm robotics: Coordination of multiple arms for large-scale, synchronized operations.

Predictive maintenance: AI algorithms preemptively address wear-and-tear issues.

Circular economy integration: Automated disassembly of returned panels for recycling.

Robotic arms are no longer a luxury—they are a strategic necessity for panel manufacturers seeking to thrive in a competitive, sustainability-driven market. By combining strength, precision, and adaptability, these machines empower plants to achieve:

Peak efficiency: Unmatched throughput and uptime.

Superior quality: Consistency and defect-free output.

Future readiness: Scalability for emerging technologies and market demands.

As industries pivot toward Industry 4.0, robotic arms stand as the backbone of smarter, greener, and more profitable panel production.

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd