In the demanding world of wood product manufacturing, from furniture and cabinetry to construction materials, efficiency and precision in material handling are non-negotiable. Introducing our state-of-the-art Robotic Arm system, a complete automation solution engineered specifically for the seamless and reliable handling of wood panels. This integrated system, centered on a high-performance Column-Mounted Palletizing Robot, is designed to optimize your production line, minimize operational costs, and maximize throughput.

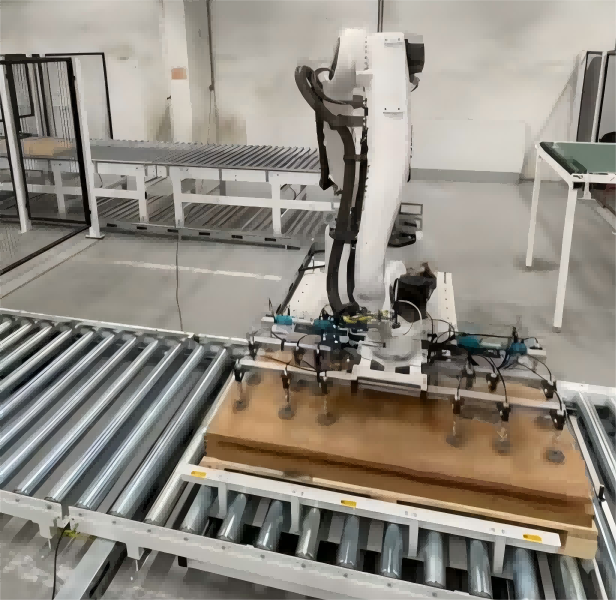

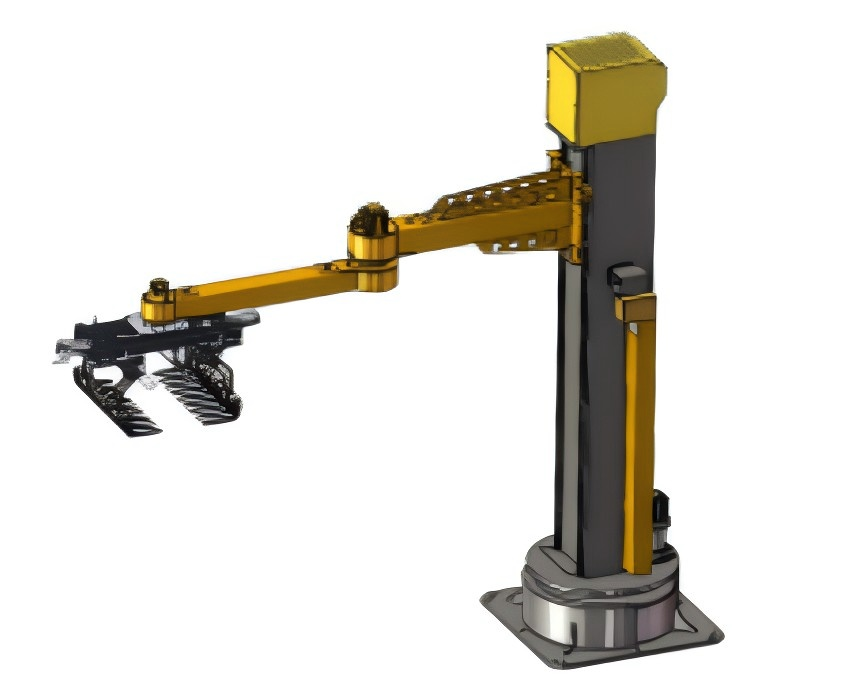

Our solution is more than just a robot; it's a synchronized ecosystem of advanced components working in perfect harmony. The core of this system is the Column-Mounted Palletizing Robot, a model of strength and stability. Unlike traditional articulated robots that require significant floor space, this Industrial Robot is anchored to a robust column, offering a compact footprint that maximizes your valuable production area. It is complemented by a high-capacity Vacuum Gripper and an Infeed Roller Conveyor, creating a seamless flow from pickup to placement. The entire operation is managed by a centralized Electrical Cabinet, ensuring reliable power and sophisticated control. This integrated approach to Wood Panel Palletizing sets a new standard for automation in the industry.

Superior Strength and Precision:

Our Column-Mounted Palletizing Robot is built for heavy-duty performance. With a high Payload Capacity, it effortlessly handles large, heavy wood panels such as MDF, plywood, and particle board. The rigid column-mounted structure ensures exceptional stability, which translates into remarkable Repeatability of ±0.2mm. This precision guarantees that every panel is placed exactly where it needs to be, cycle after cycle, eliminating product damage and ensuring perfect, stable pallet loads.

Gentle and Adaptive Handling with Advanced EOAT:

The end-of-arm-tooling is critical for delicate surfaces like wood. Our custom-engineered Vacuum Gripper is equipped with multiple rubber suction cups, creating a secure and evenly distributed grip that prevents scratching or warping. The system can be tailored with various suction cup layouts and vacuum levels to accommodate different panel sizes, finishes, and weights, providing unparalleled flexibility for mixed-product environments. This Automated Handling process is not only efficient but also preserves the quality of your finished products.

Optimized Workflow and Continuous Operation:

The integration of the Infeed Roller Conveyor is a key component of our system's efficiency. This conveyor seamlessly presents panels to the Robotic Arm Palletizer, creating a consistent and predictable Material Handling workflow. The robot's high cycle rate of 400 cycles per hour ensures a continuous, high-speed operation that manual labor or less integrated systems cannot match. This seamless Loading/Unloading process drastically reduces bottlenecks, allowing your production line to achieve its full potential.

Durability and Reliability for Industrial Environments:

Designed for the rigors of a woodworking facility, our Palletizing Robot boasts an IP55 rating for its body, protecting it against dust and moisture commonly found in these settings. The accompanying Electrical Cabinet has an IP54 rating, safeguarding the sensitive controls from particulate ingress. This robust construction ensures maximum uptime and a long operational life, even in challenging conditions, providing an excellent return on investment.

This Robotic Arm system is perfectly suited for a wide range of applications within the wood industry:

Automatic Palletizing/Depalletizing: Systematically building stable pallets of finished panels for shipment or retrieving raw panels for processing.

Machine Tending: Automatically Loading and Unloading panels into and out of CNC machines, saws, or sanding equipment, enabling lights-out manufacturing.

Order Picking and Sorting: Automating the process of sorting panels by size, type, or customer order, significantly improving logistics accuracy.

Model | KUCAJAM100 | KUCAJAM110 |

Cycle Parameter | 400 f/h (Cycles per hour) | |

Number of Axes | 4-axis | |

Payload Capacity | 130kg | |

Repeatability | ±0.2 mm | |

Max. Arm Reach | 2800 mm | 2900mm |

Robot Body IP Rating | IP55 | |

Ambient Temperature | 0 ~ 45 °C | |

Robot Body Weight | 1290kg | 1350kg |

Function | Material Handling, Loading/Unloading | |

Maximum Motion | X-axis: 3000 mm Y-axis:2800 mm Z-axis: ±330° R-axis: ±330° | X-axis: 3000 mm Y-axis:2900 mm Z-axis: ±330° R-axis: ±330° |

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd