In the sophisticated realm of wood panel manufacturing, the journey from raw log to premium sheet is fraught with challenges. Nowhere is this more evident than in the final, yet most delicate, stage: drying thin veneer sheets. When sheets thinner than 0.8mm are peeled or sliced, they enter a state of extreme vulnerability. Their cellular structure is exposed, their moisture content is uneven, and their inherent beauty is easily compromised. At this juncture, the humble mesh belt ceases to be a mere conveyor component; it transforms into the critical guardian of quality, ensuring each precious veneer sheet emerges from the dryer flawless and ready for lamination.

Our specialized mesh belts are the definitive solution for drying these ultra-thin veneer sheets, meticulously engineered to prevent warping, sticking, and texture degradation. We understand that the right material is not a choice, but a necessity dictated by the value of the product. That is why we offer a curated selection of high-performance belts, each designed to meet a specific set of production demands.

For high-volume, cost-sensitive operations handling standard or lower-cost veneer sheets, our galvanized steel mesh belt provides an exceptional balance of durability and economy. Its robust construction withstands the rigors of continuous thermal cycling and heavy loads, making it ideal for environments where maximum tensile strength and longevity are paramount. While it performs its duty reliably, its uncoated surface can present a minor risk of surface marking or staining on highly sensitive woods. It remains a vital tool for applications where absolute surface perfection is secondary to operational resilience and cost-effectiveness.

When moderate non-stick properties and chemical resistance are required, the PTFE (Teflon) coated fiberglass mesh belt excels. Its smooth, low-friction surface prevents veneer sheets from adhering to the belt during transit, facilitating a clean release even with slightly tacky surfaces. This belt offers superior resistance to a wide range of chemicals and can operate effectively across a broad temperature range. It is a versatile choice for manufacturers seeking to improve release characteristics without the investment in premium stainless steel, particularly for medium-grade veneer sheets where some compromise on ultimate flatness is acceptable.

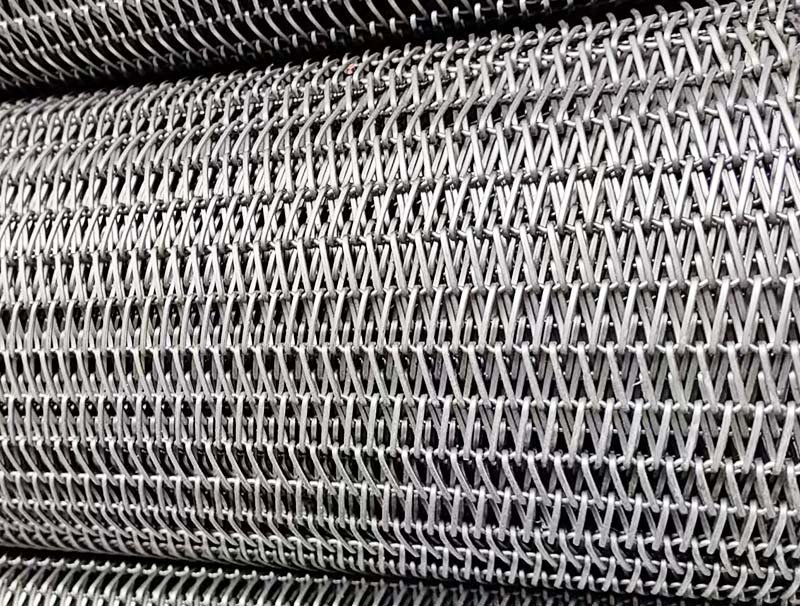

For the most discerning manufacturers producing rare, exotic, or high-value veneer sheets, our stainless steel mesh belts are the undisputed pinnacle of technology. They are specifically chosen to maximize drying flatness and preserve the intricate natural texture of the wood, ensuring the final product commands top market value.

We provide two premier grades of stainless steel, each tailored for specific excellence:

304 Stainless Steel Mesh Belt: The Epitome of Purity and Performance.

Crafted from a chromium-nickel alloy, our 304 stainless steel mesh belts represent the gold standard for applications demanding impeccable hygiene, superior corrosion resistance, and uncompromising aesthetic preservation. The inert nature of 304 stainless steel ensures zero contamination, preventing any discoloration or chemical interaction that could mar the pristine surface of precious woods like teak, walnut, or ebony. Its exceptional formability and strength allow for precise weave patterns that cradle each veneer sheet, providing uniform heat distribution for perfect, wrinkle-free drying. This belt is essential for manufacturers whose reputation is built on delivering flawless face veneers for luxury furniture and architectural panels.

201 Stainless Steel Mesh Belt: Optimized Strength and Value.

Our 201 stainless steel mesh belts offer a compelling combination of high strength, excellent corrosion resistance, and notable cost savings compared to 304 grade. Alloyed primarily with manganese and nitrogen, it retains much of the performance of its higher-end counterpart while being significantly more economical. This makes it an intelligent choice for drying high volumes of valuable veneer sheets where ultimate corrosion resistance is needed, but the extreme purity of 304 is not a strict requirement. It delivers outstanding flatness and texture preservation, protecting your investment in quality wood while optimizing operational expenditure.

Selecting the correct mesh belt is a direct investment in your product's quality and your company's bottom line. Our experts can analyze your specific veneer types, production speeds, and drying parameters to recommend the optimal belt. Ensure your precious veneer sheets receive the protection they deserve. Contact us today to discuss how our precision-engineered mesh belts can elevate your drying process.

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd