When it comes to drying ultra-thin veneers—especially those below 0.8mm in thickness—precision, durability, and material compatibility are non-negotiable. These delicate sheets, often derived from premium hardwoods like ash and white oak, demand a drying process that preserves their integrity, color, and grain while ensuring consistent moisture removal. At the heart of this critical operation lies the mesh belt dryer, and more specifically, the choice of stainless steel mesh belt—a component that can make or break the quality and efficiency of your veneer drying line.

Veneers thinner than 0.8mm are inherently fragile. Their thinness means they dry faster but are also more prone to warping, cracking, or discoloration if exposed to uneven heat, mechanical stress, or chemical reactions with the drying belt. For high-value species like ash and white oak, even minor defects can render entire batches unsellable, leading to significant financial losses. This is where stainless steel mesh belts prove indispensable.

Unlike traditional carbon steel or synthetic belts, stainless steel offers unmatched chemical inertness, meaning it won’t react with the natural resins, tannins, or oils found in premium woods. This prevents staining, discoloration, or unwanted chemical transfers that could degrade the veneer’s aesthetic appeal. For manufacturers working with luxury hardwood veneers, where appearance is everything, stainless steel ensures the final product retains its natural beauty and market value.

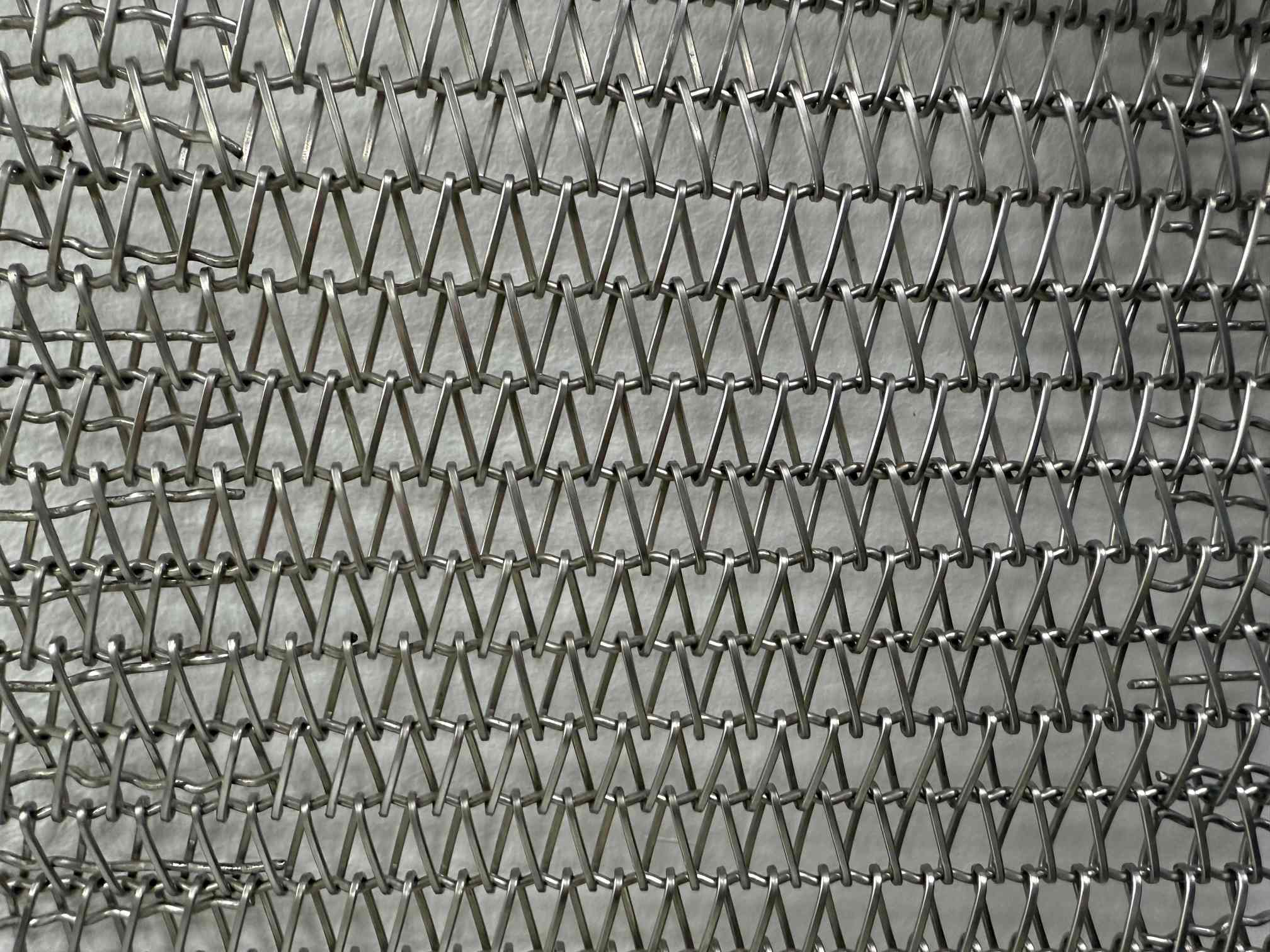

A mesh belt dryer is the preferred choice for thin veneer drying because it provides uniform airflow, consistent temperature distribution, and gentle handling—all critical factors for preventing defects in low-thickness materials. The stainless steel mesh belt serves as the conveyor system that carries the wet veneers through the drying chamber, exposing them to controlled heat and air circulation.

For ash and white oak, which often have dense fibers and high natural oil content, the drying process must be carefully calibrated to avoid surface checking or internal stress fractures. Stainless steel belts excel in this environment because they:

Maintain structural integrity at high temperatures (often up to 180°C or more), ensuring no deformation or warping under prolonged heat exposure.

Provide excellent air permeability, allowing for optimal moisture evaporation without obstructing airflow.

Resist abrasion and corrosion, extending lifespan even with continuous use of abrasive or resin-rich wood species.

While carbon steel belts may seem like a cost-saving option initially, they come with significant drawbacks for high-end veneer drying:

Corrosion Risk: Exposure to moisture and wood extracts can lead to rust, which may transfer to the veneer surface, causing permanent stains.

Staining & Contamination: Carbon steel can react with certain wood species, altering their color or leaving metallic residues.

Shorter Lifespan: Without proper coatings, carbon steel belts wear out faster under high heat and abrasive conditions, leading to more frequent replacements and downtime.

In contrast, stainless steel mesh belts are:

✅ Hygienic & Non-Reactive: Ideal for food-contact-grade veneers or applications where purity is critical.

✅ Long-Lasting: With proper maintenance, they can endure years of continuous operation without degradation.

✅ Low Maintenance: No need for frequent painting or anti-corrosion treatments, reducing operational costs.

At Shine Machinery, we understand that every veneer drying operation is unique. That’s why we offer bespoke stainless steel mesh belts tailored to your specific mesh belt dryer setup, wood species, and drying parameters. Whether you’re processing ash, white oak, or other high-value timbers, our belts are engineered to:

Match your dryer’s width, pitch, and mesh size for seamless integration.

Withstand your target drying temperature and airflow requirements.

Minimize veneer sticking, tearing, or misalignment during the drying cycle.

For manufacturers of premium thin veneers, the choice of drying equipment—and especially the stainless steel mesh belt—is a critical decision that impacts product quality, operational efficiency, and profitability. By opting for a mesh belt dryer equipped with high-grade stainless steel mesh belts, you ensure that your ash, white oak, and other valuable veneers emerge from the drying process flawless, consistent, and ready for high-end applications.

Don’t let subpar materials compromise your veneer’s potential. Upgrade to stainless steel mesh belts and experience the difference in durability, performance, and peace of mind. Contact us today to learn how we can optimize your veneer drying line for maximum efficiency and quality.

Copyright By © Shandong Shine Machinery Co.,Ltd