The relentless advancement of technology has propelled robotic automation to the forefront of industrial innovation, and the panel processing industry is experiencing a transformative shift. The integration of industrial robotic arms is fundamentally reshaping traditional manufacturing workflows, moving production lines towards unprecedented levels of automation. This evolution is not merely about replacing manual labor; it's about achieving step-change improvements in efficiency, precision, and workplace safety. As these technologies mature, their application in handling materials like wood panels, composites, and plastic sheets is becoming a critical benchmark for modern, competitive manufacturing. The precision and programmability of a robotic arm make it an indispensable asset for tasks ranging from the simplest pick-and-place to complex machining operations, ensuring consistent, high-quality output in a demanding industrial environment.

The challenges inherent in traditional panel processing—labor-intensive workflows, inconsistent quality, and significant safety risks—are effectively addressed by the strategic deployment of industrial robotic arms. This document explores how this technology is revolutionizing the industry.

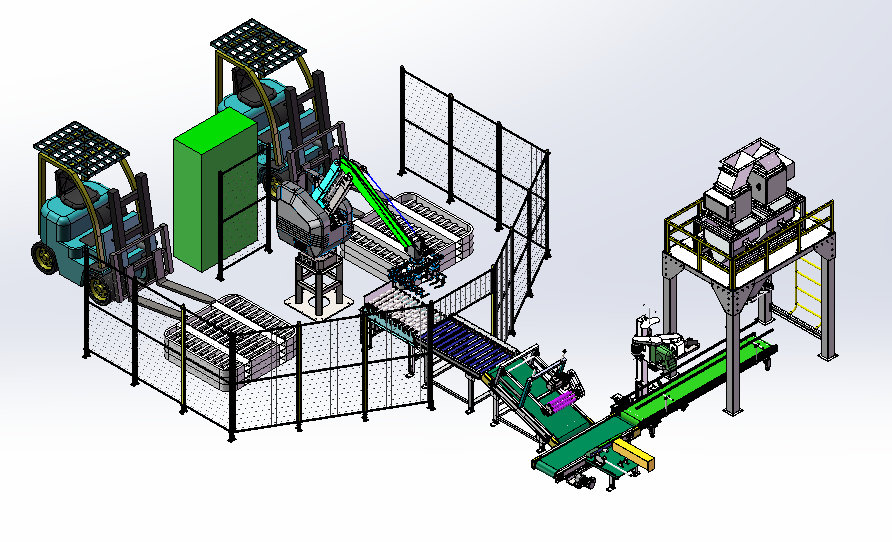

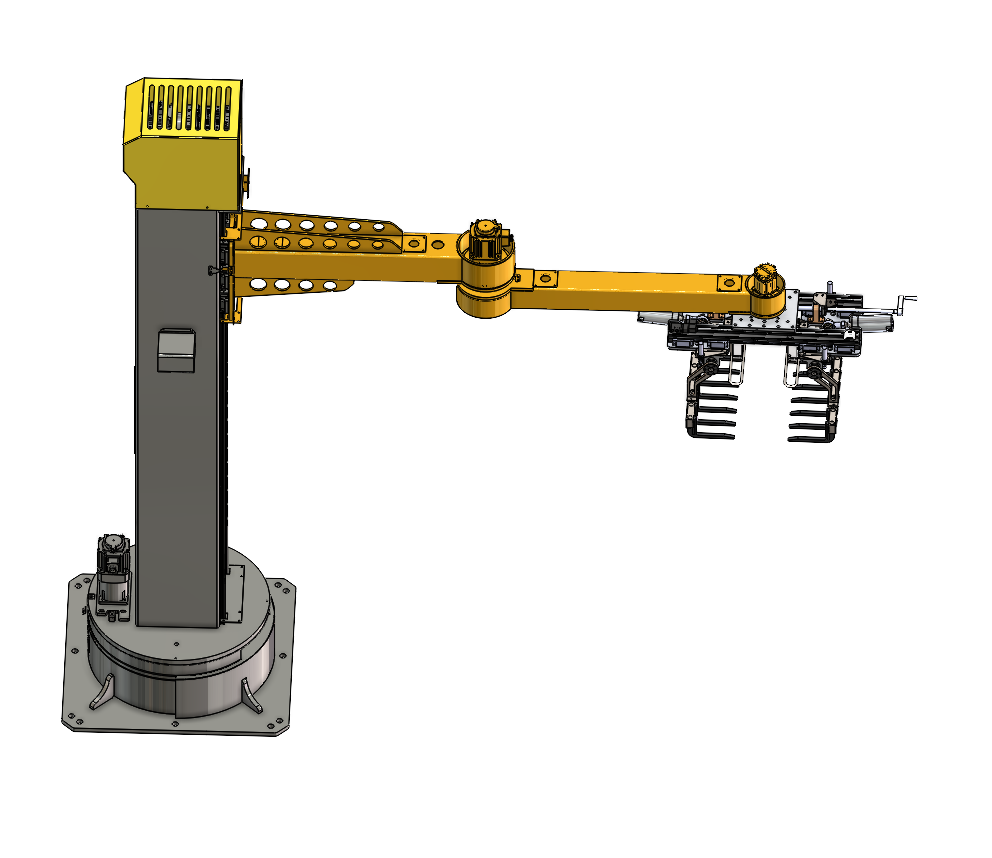

Traditional panel handling is characterized by inherent bottlenecks. Manual loading of saws, presses, and finishing machines is time-consuming, physically demanding, and a major constraint on overall production speed. The introduction of industrial robotic arms shatters these limitations. These systems are engineered for continuous, uninterrupted operation, dramatically accelerating cycle times. A single robotic arm can seamlessly manage the flow of panels between different stations—from the initial offloading of a CNC router to the subsequent placement of the cut parts onto a nesting table or into a finishing cell. This creates a seamless, continuous production stream, eliminating the natural pauses and fatigue associated with human workers. The result is a substantial increase in throughput and a significant reduction in lead times, allowing manufacturers to meet demanding schedules with greater reliability.

In panel processing, precision is not just a goal; it is an absolute requirement. The slightest deviation in a cut, drill, or groove can render a component useless, leading to costly material waste and rework. Human operators, despite their skill, are subject to variations in concentration and physical stamina, which can introduce inconsistencies. Industrial robotic arms, however, deliver unwavering accuracy. Programmed with exact digital blueprints, a robotic arm executes every movement with repeatability measured in fractions of a millimeter. Whether performing high-speed milling, intricate drilling, or precise gluing, the robotic arm ensures that every single panel is processed identically. This exceptional consistency drastically reduces material waste from errors and ensures that every product meets the highest quality standards, enhancing brand reputation and customer satisfaction.

A panel processing facility presents numerous potential hazards, including sharp panel edges, the risk of heavy loads being dropped, and exposure to noise and dust from machining operations. The deployment of a robotic arm to handle these dangerous tasks is a decisive step towards a safer workplace. These machines excel in environments that are hazardous to humans, tirelessly moving heavy sheets and performing repetitive tasks without risk of accident or strain. By removing workers from the most dangerous aspects of the production process, industrial robotic arms significantly reduce the incidence of workplace injuries. This not only protects employees but also lowers associated costs such as insurance premiums and downtime from accidents.

Within the ecosystem of robotic automation, the gantry robot (or Cartesian robot) holds a particularly important place for panel handling. This system excels in creating highly automated production cells. It can manage the entire material flow—from loading raw panels onto a machining center, positioning them with absolute accuracy during clamping, to unloading finished parts. This integration drastically reduces intermediate handling stages. Equipped with advanced vacuum grippers, the gantry robotic arm can gently but securely grasp and move even the largest and most delicate panels without causing surface scratches or other damage. This non-marking handling is essential for applications where surface integrity is paramount, such as for high-pressure laminates or pre-finished materials.

The future of industrial robotic arms in panel processing lies in intelligence and connectivity. The integration of Artificial Intelligence (AI) and Machine Learning (ML) is paving the way for a new generation of smart robots. These systems will be capable of adapting to minor variations in panel size or orientation, making real-time adjustments to their programs. Vision systems will allow a robotic arm to identify part numbers, inspect for defects, and optimize cutting patterns on the fly to maximize material yield. As the technology becomes more accessible and cost-effective, the adoption of industrial robotic arms will become standard practice, not just for large corporations but for small and medium-sized enterprises as well.

In conclusion, the adoption of industrial robotic arms is a definitive competitive advantage in the modern panel processing industry. The benefits are clear and compelling: dramatic gains in efficiency, guaranteed precision and quality, and a safer working environment. As technology continues to evolve, these systems will become even more intelligent, flexible, and integral to successful manufacturing. For any forward-thinking company, integrating this technology is not just an upgrade—it is an essential strategic move for future growth and sustainability.

Copyright By © Shandong Shine Machinery Co.,Ltd