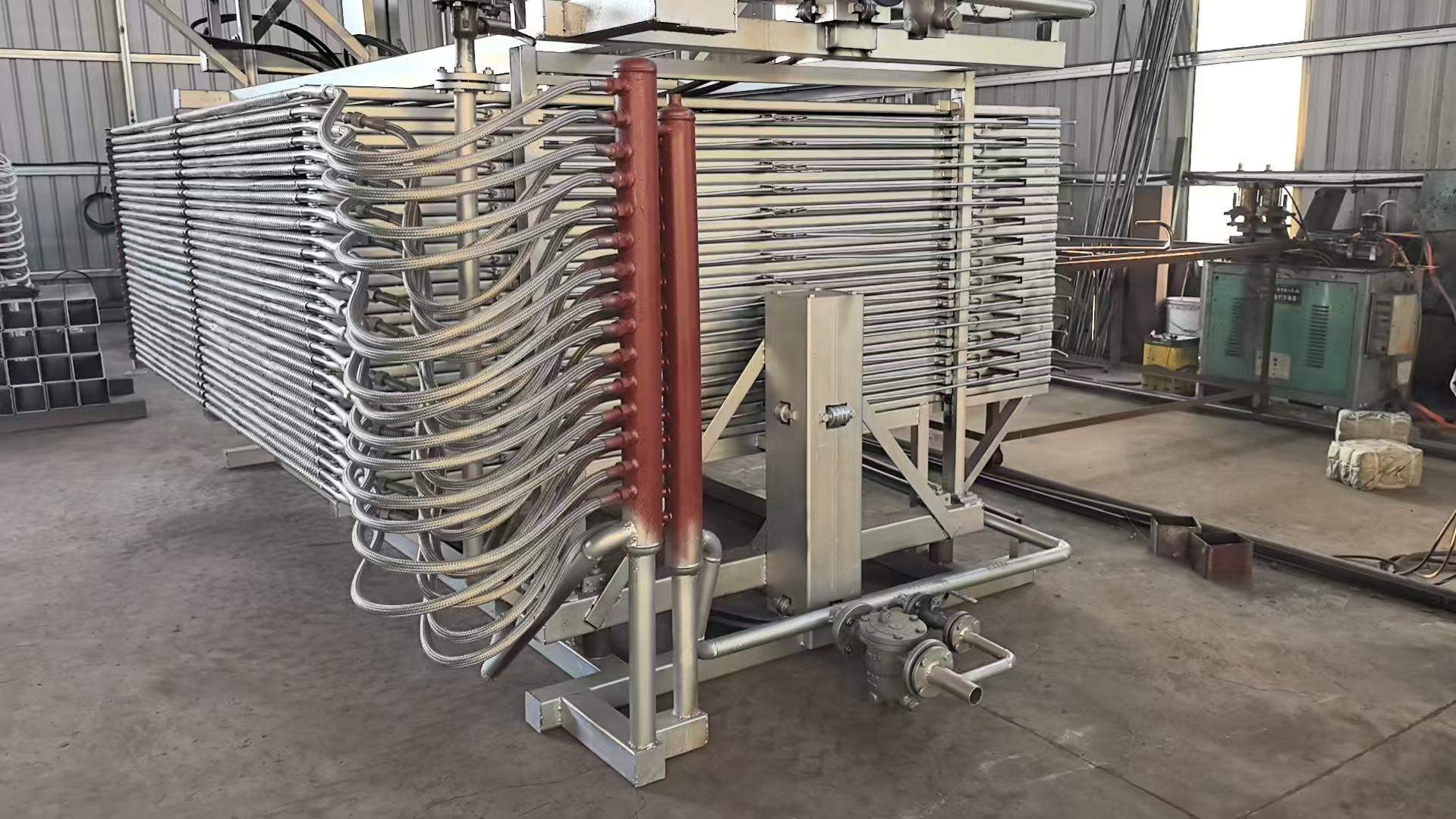

The DH-30 Multi-Layer Vertical Veneer Dryer is specially designed for the plywood industry, delivering high-efficiency, energy-saving, and superior drying performance to help enterprises reduce costs, enhance productivity, and redefine the veneer drying experience.

Precisely adapted to mainstream plywood veneer sizes, the DH-30 effortlessly handles both large and small veneers. For 4*8ft (1.27m×0.64m) large veneers, the dryer accommodates 30 layers per cycle, with 16 veneers per layer, achieving a maximum load capacity of 480 veneers per cycle. For 36-ft (0.97m×0.48m) small veneers, it fits 30 layers per cycle, with 24 veneers per layer, enabling a single cycle to process 720 veneers. With a drying time of just 30-40 minutes per cycle, the DH-30 achieves a processing capacity of 1-1.2m3 per hour, ensuring stable and efficient output to meet the demands of large-scale production.

Dual Savings in Space and Labor

The DH-30 occupies only about 7 square meters of floor space, with an additional 25 square meters of operational space, significantly reducing venue rental costs. Its user-friendly design allows a group of 3 units to be operated by just 2 workers, drastically cutting labor input and operational expenses.

Reduced Veneer Stockpiling Losses

By minimizing veneer stockpiling, the DH-30 prevents quality degradation and storage costs caused by long-term storage, comprehensively lowering enterprise operational expenditures.

Featuring a unique direct-contact drying design, the heat dissipation plates gently “cradle” the veneers during drying. This design prevents cracking and carbonization as the veneers shrink, while ensuring the veneers remain flat throughout the process to avoid warping or deformation. The dried veneers exhibit superior quality, with an average moisture content precisely controlled between 0-8%, laying a solid foundation for high-quality plywood production.

The DH-30 excels in energy performance with flexible energy adaptation. A 1-ton boiler can power 3 dryers, while a 2-ton boiler can support 6-8 units, accommodating diverse enterprise energy configurations. Its power consumption is surprisingly low: only the lifting mechanism requires electricity, with each unit equipped with a 3kW motor, resulting in a daily power consumption of just 3-5 kWh. This significantly reduces energy costs, enabling green and efficient production.

DH-30-2.6: Specially designed for 1.27m×0.64m large veneers, it features a drying area of 2.85m×2.6m. Despite its compact 7-square-meter footprint, it delivers efficient drying for large veneers, meeting diverse production needs.

DH-30-2.0: Tailored for 0.97m×0.48m small veneers, it boasts a drying area of 3.41m×2.0m. Within the same 7-square-meter space, it ensures high-efficiency and high-quality drying for small veneers.

The DH-30 Multi-Layer Vertical Veneer Dryer, integrating advanced technology and exceptional performance, has become a powerful assistant for plywood enterprises to enhance competitiveness and achieve high-quality development.

Copyright By © Shandong Shine Machinery Co.,Ltd