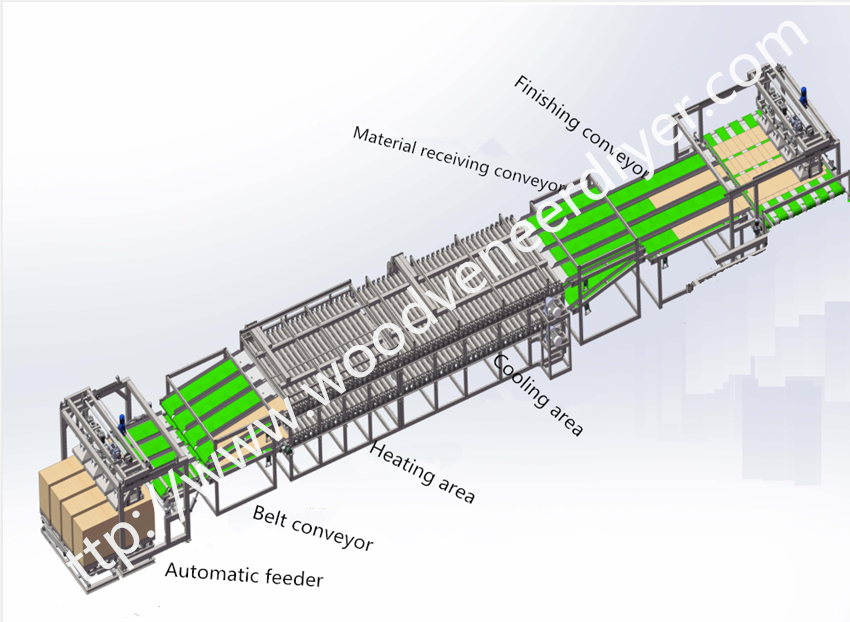

The Shine 20-56 m 2-deck roller veneer dryer is a high-performance wood veneer dryer designed for efficient veneer drying across various wood processing applications. This versatile wood veneer drying equipment features customizable lengths (20m-60m, with 4m sections) to meet specific production needs. Its advanced drying system utilizes a scientific airflow design where hot air from centrifugal blowers is evenly distributed through upper/lower bellows nozzles, ensuring uniform veneer drying across the entire wood veneer surface. The precision control system incorporates an endless gearbox to automatically adjust feed speed based on veneer thickness and moisture content for optimal drying results. For material handling, the innovative transmission system uses counter-rotating rollers that gently transport wood veneer while applying consistent pressure, producing flawlessly smooth, mark-free dried veneer. Multiple heating options, including steam, thermal oil, hot air furnace, or biomass combustion (using waste wood), make this veneer dryer adaptable to different energy requirements. This comprehensive wood veneer dryer solution combines cutting-edge drying technology with flexible configuration options to deliver exceptional veneer drying performance for plywood and furniture manufacturing applications.

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 2 | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m) | 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.8-1.1 | 1.1-1.4 | 1.5-1.8 | 1.8-2.2 | 2-2.5 | 2.4-2.7 |

Heat exhaustion(10000 kcal) | 28-38.5 | 38.5-49 | 52.5-63 | 63-77 | 70-87.5 | 84-94.5 |

Traction motor power(kw) | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 |

Hot air fan power (kW) | 11*4 | 11*5 | 11*6 | 11*7 | 11*8 | 11*9 |

Air cooling fan power(kW) | 11 | 11 | 11 | 11 | 11 | 11 |

| Total power (kW) | 66 | 77 | 88 | 99 | 110 | 121 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m) | 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kw) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

Air cooling fan power(kW) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kW) | 132 | 147 | 158 | 169 | 180 |

| Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

High-Efficiency Drying

Double-deck design maximizes drying capacity while saving floor space

Uniform hot air circulation ensures consistent moisture removal

Advanced Heating Options

Multiple heat sources available: steam, thermal oil, hot air furnace, or biomass

Energy-saving design reduces fuel consumption

Precision Control System

Automatic speed adjustment based on veneer thickness and moisture content

User-friendly interface for easy operation

Superior Drying Quality

Unique roller system prevents veneer deformation

Produces smooth, flat veneer without marks

Customizable Configurations

Standard lengths from 20-56 meters (extendable to 60m)

Modular 4m sections for flexible layout

Durable Construction

Heavy-duty components ensure long service life

Low-maintenance design

Strength of Shine Machinery

Certification of Shine Wood Veneer Dryer

Shine's double-deck veneer dryer holds multiple patent certifications and meets international export qualifications, demonstrating its proven technology and global compliance.

Shipping & Packaging

Shine implements rigorous packing and container loading procedures to ensure our veneer dryers arrive in perfect condition worldwide.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd