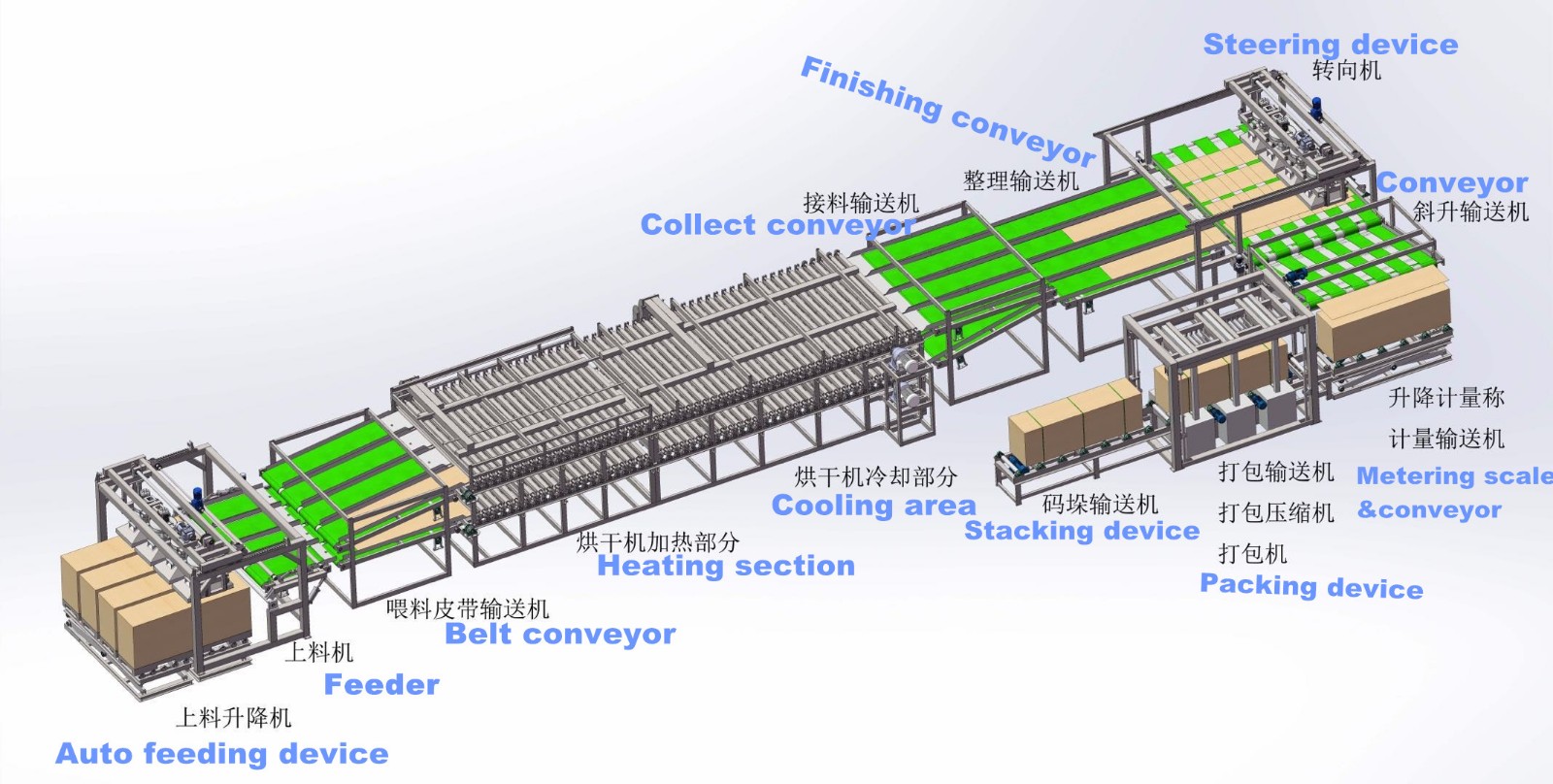

Shine Roller Type Veneer Dryers Introduction

The plywood veneer dryer produced by Shandong Shine Machinery Co., Ltd. is widely used in flatting drying of high-grade plywood, multi layer board and architectural core face veneer. Shine roller veneer drying equipment is equipped with environmental protection type hot air stove. its characteristics: save fuel, twice use of hot air , increase heating speed.the veneer after drying is flat,moisture content is up to national standard. Equipped with integral type high efficiency energy saving hot air stove. No boiler and other auxiliary equipment, no use water,coal, electricity. Rind ,wood chips and wood craps are all can be as fuel. and can quickly achieve the heat required by the veneer dryer machine.

Technical Parameter for Shine Roller Type Veneer Dryers

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kw) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

Air cooling fan power(kw) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kw) | 132 | 147 | 158 | 169 | 180 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

1.Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect.

2.The biomass burner is Shine patented product. It can burn all kinds of waste wood directly to reduce the drying cost to the most.

3.The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

4.The veneer after drying is free of splits and the surface is in good condition for gluing.

5.Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

6.Automatic electric control system with merits of saving labor cost, easy operation and low failure rate. Main electrical components are international famous brands.

7.Shine veneer dryer adopts frequency conversion ,which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect

8.Less maintenance is required for Shine veneer dryer and no veneer jamming leading to less downtime.

9.We have a professional R&D team that can design different models according to customer’s special requirement.

10.We have perfect after-sale service system, which can supply 24h online service; remote operation is available on request, regular customer visits, sufficient spare parts supply in time.

Shine Company Introduction

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd