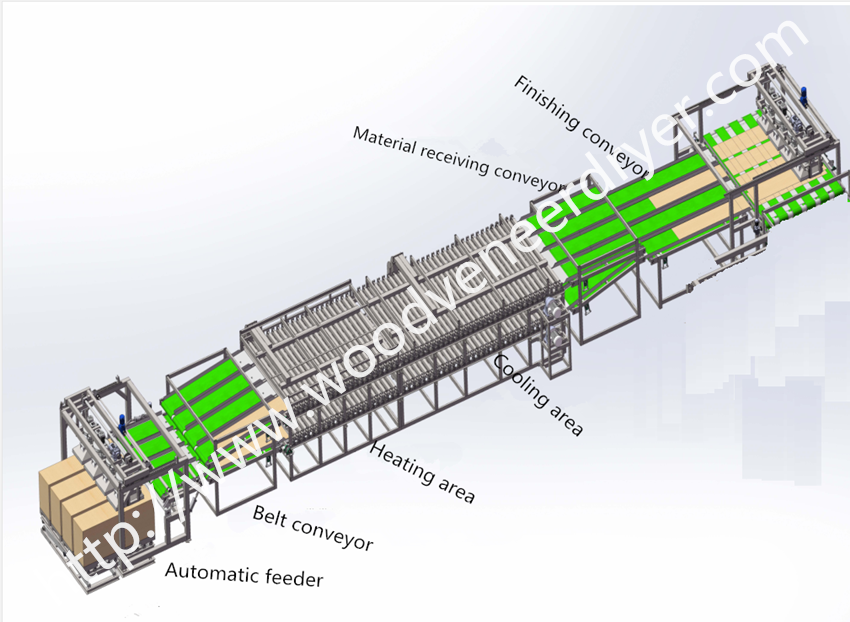

Gas fired integrated veneer drying line uses combustible gases such as natural gas and coal gas as media. The generated flue gas is processed by the heat transfer structure independently developed by our company. The drying blower and the heat transfer hot air are directly blown into the air pipe to dry the veneer. The heat energy is directly used by 100%, and the drying temperature is high (drying room maintaining 200 ℃), there are two major advantages of saving fuel (without any external heat emission, and all the heat is concentrated in the drying room). Analysis of coal consumption: Semi-dry veneer is dried in 26 meter-long dryer equipment, 80-100 m³of veneer cost about 400-500 kg of coal.The fresh veneer is dried in a 26 meter-long drying zone, 80-100 cubic meters of veneer cost about 100-700kg of coal. Conventional dryers generally use independent hot air stoves as heat sources, consume large quantities of coal, consume large amounts of electricity. They are environmentally polluted, have large volume, complex structure, high drying cost, low utilization of thermal energy, large power consumption of the whole machine and high manufacturing cost. except for gas fired integrated veneer drying machine , Shine machinery also can make electric heating plywood dryer , conduction oil heating plywood veneer drying machine, biomass veneer dryer machines.

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.5-0.65 | 0.65-0.8 | 0.8-1 | 1-1.2 | 1.15-1.35 | 1.3-1.5 |

Heat exhaustion(10000 kcal) | 17.5-23 | 23-285 | 28-35 | 35-42 | 40.25-47.25 | 45.5-52.5 |

Traction motor power(kw) | 7.5 | 7.5 | 5.5 | 5.5 | 5.5 | 5.5 |

Hot air fan power (kw) | 7.5*4 | 7.5*5 | 7.5*6 | 7.5*7 | 7.5*8 | 7.5*9 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Total power (kw) | 45 | 52.5 | 58 | 65.5 | 73 | 80.5 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect.

3.Shine roller veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements.which can meet different customers' requirements.

Copyright By © Shandong Shine Machinery Co.,Ltd