Advanced and Durable Veneer Dryer Description

Plywood veneer roller dryer is an important machine in the drying section of plywood. Shine wood veneer dryer has merits of high productivity, energy efficiency, the lowest drying cost, and a perfect drying effect. Veneer drying machine equipped with an automatic electric control system, which has features of saving labor cost, easy operation, and a low failure rate. An exciting new development for Shine drying veneer machine is that a 20m 1deck veneer dryer machine project was completed through a customer's factory in Malaysia recently. We have professional R&D that can design different types of veneer dryers for users.

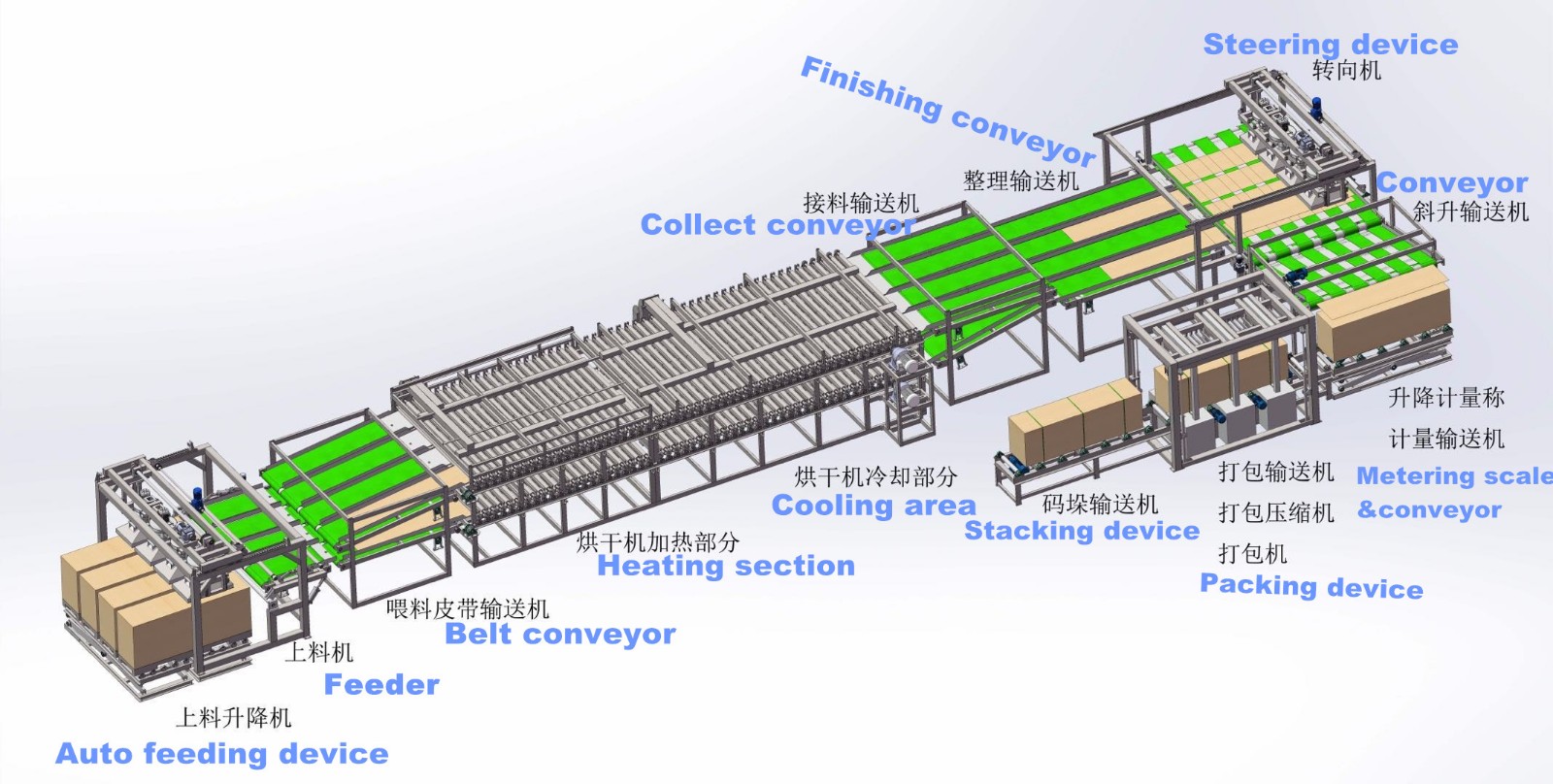

Shine Advanced and Durable Veneer Dryer Pictures

Whether for plywood manufacturing or decorative veneer production, our 4-deck veneer drying machine is the ideal solution for businesses seeking high-performance, high-capacity wood veneer drying.

Technical Parameter for Advanced and Durable Veneer Dryer

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m) | 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kW) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

| Air cooling fan power(kW) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kW) | 132 | 147 | 158 | 169 | 180 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

Product Core Advantages

1. High-efficiency multi-layer drying design

Adopting a 4-deck veneer drying structure, multi-layer synchronized drying greatly improves the handling capacity of veneer, meeting the demand of large-scale production, and increasing the drying efficiency by more than 300% compared with the traditional single-layer dryer.

2. Excellent drying performance

Intelligent temperature control system: precisely adjust the temperature (maximum 500°C, minimum -20°C), to adapt to the veneer drying needs of different species (such as birch, poplar, oak, etc.), to ensure that the moisture content is uniformly up to standard (± 2% error).

Energy saving and environmental protection: hot air recycling technology reduces energy consumption by 30%, in line with green production standards.

3. High durability and low maintenance

φ102 seamless steel tube roller: anti-deformation, corrosion-resistant, guaranteeing long-term stable operation.

Oil-free high-temperature bearings: Patented bearings can withstand extreme temperatures without frequent lubrication, reducing downtime for maintenance.

4. Fully automated operation

Equipped with an Auto Feeder and Smart Collector, it realizes full automation from drying to stacking, saving labor cost and eliminating secondary damage.

Factory Comprehensive Advantage

1. Technology R&D Strength

With 20 years + wood drying equipment manufacturing experience, national high-tech enterprise certification, continuous innovation in veneer drying technology, and more than 50 patented technologies.

2. A strict quality control system

From steel selection to machine testing, the implementation of ISO9001 quality management standards, each unit of equipment undergoes 72 hours of continuous testing to ensure that the factory has zero defects.

3. Customized service capability

We support the customization of wood veneer dryer size, number of decks (2-6 decks optional) and heat source (gas/steam/electric heating) according to customers' needs, and provide one-on-one drying solution design.

4. Global Project Experience

Our products are exported to 30+ countries in Southeast Asia, South America, Africa, etc. We have served more than 500 customers, including famous plywood companies (e.g., Guangxi Fenglin Group, Indonesia Kayu Lapis).

5. After-sales guarantee

Provide 24-hour remote technical support + 48 hours on-site response, key components of the lifetime warranty to ensure that customers have no worries.

Shine Machinery not only focuses on the R&D and production of wood veneer dryers, but also establishes a strict standardized loading and logistics management system to ensure that every 4-deck veneer drying machine is safely and efficiently delivered to the global customers.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd