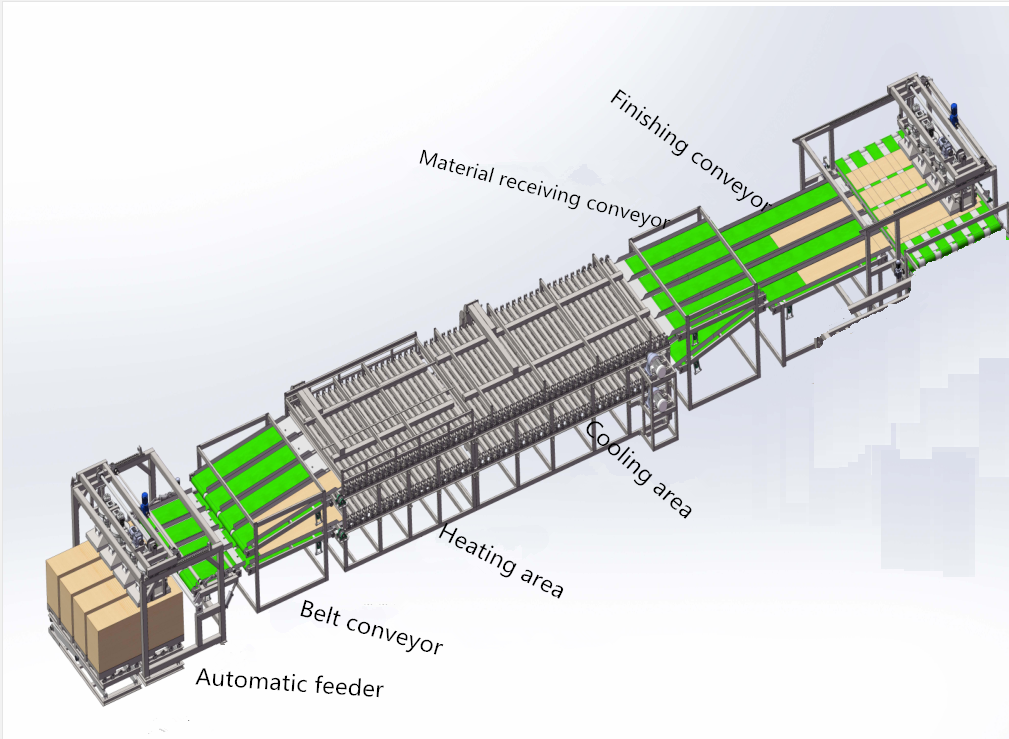

Shine normal roller veneer dryer includes 20-60m and 1-3 deck, the capacity of 44m veneer dryer machine is about 40cbm/day. the capacity will be different according to different moisture of veneer and the thickness . also we can design special models according to customer's special requirements.The veneer dryer produced by Shandong Shine Machinery Co., Ltd. is widely used in flatting drying of high-grade plywood, multi layer board and architectural core face veneer. Shine roller veneer drying equipment is equipped with environmental protection type hot air stove. its characteristics: save fuel, twice use of hot air , increase heating speed.the veneer after drying is flat,moisture content is up to national standard. Equipped with integral type high efficiency energy saving hot air stove. No boiler and other auxiliary equipment, no use water,coal, electricity. Rind ,wood chips and wood craps are all can be as fuel. and can quickly achieve the heat required by the veneer dryer.

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Deck | 1 | 1 | 1 | 1 | 1 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 1.5-1.7 | 1.65-1.8 | 1.7-1.9 | 1.8-2 | 1.9-2.2 |

Heat exhaustion(10000 kcal) | 52.5-59.5 | 57.75-63 | 59.5-66.5 | 63-70 | 66.5-77 |

Traction motor power(kw) | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Hot air fan power (kw) | 7.5*10 | 7.5*11 | 7.5*11 | 7.5*12 | 7.5*13 |

Air cooling fan power(kw) | 7.5 | 7.5 | 7.5*2 | 7.5*2 | 7.5*2 |

Total power (kw) | 88 | 97.5 | 105 | 112.5 | 120 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

1. The veneer after drying by Shine veneer dryer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect.

3.Shine roller veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements.which can meet different customers' requirements.

Shine Company Infomration

Shandong Shine Machinery Co.,Ltd is a large-scale enterprise specializing in R&D and production of veneer rotary cutting and veneer dryer equipment under the Shandong Wanda Heavy Industry Co., Ltd. Since its inception, the company has been adhering to the vision of “making first-class corporate contributions, building first-rate enterprise talent, creating first-class corporate brand,implementing modern enterprise management system, using new sales concepts and service systems, and investing 10 million yuan in scientific research each year. It also combine industrial universities to study high-end technology, so that Shine's veneer dryer products are always at the forefront of the industry's technology.

The company is located at the intersection of National Road 105 and National Road 308. It has 10 standardized workshops, covers an area of 70000 square meter, and has a building area of 12,000 square meters. It has 150 sets of various equipments and has complete machining, heat treatment, punching, welding, and assembly, painting these six production lines.The advanced equipment, exquisite craftsmanship, and advanced research and development make the Shine veneer dryer products have many advantages such as reasonable design, reliable performance, high quality, low energy consumption, easy operation, and high output. Products are sold to various provinces and cities in the country, and exported to Russia, South Africa, Southeast Asia and many other countries and regions.

The company's veneer dryer line and veneer peeling line have won the unanimous praise of our customers with high precision and high cost performance. With perseverance in the spirit of struggle and work attitude of excellence.Shine Intelligent will leave a solid footprint in the process of China's industrial modernization and the development of urban development.

To provide value-added services and solution to customers is the purpose of Shine Machinery. Integrity casts brand and brand leads the market. With our efforts and the trust of our customers, we and our customers will be more successful.

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd