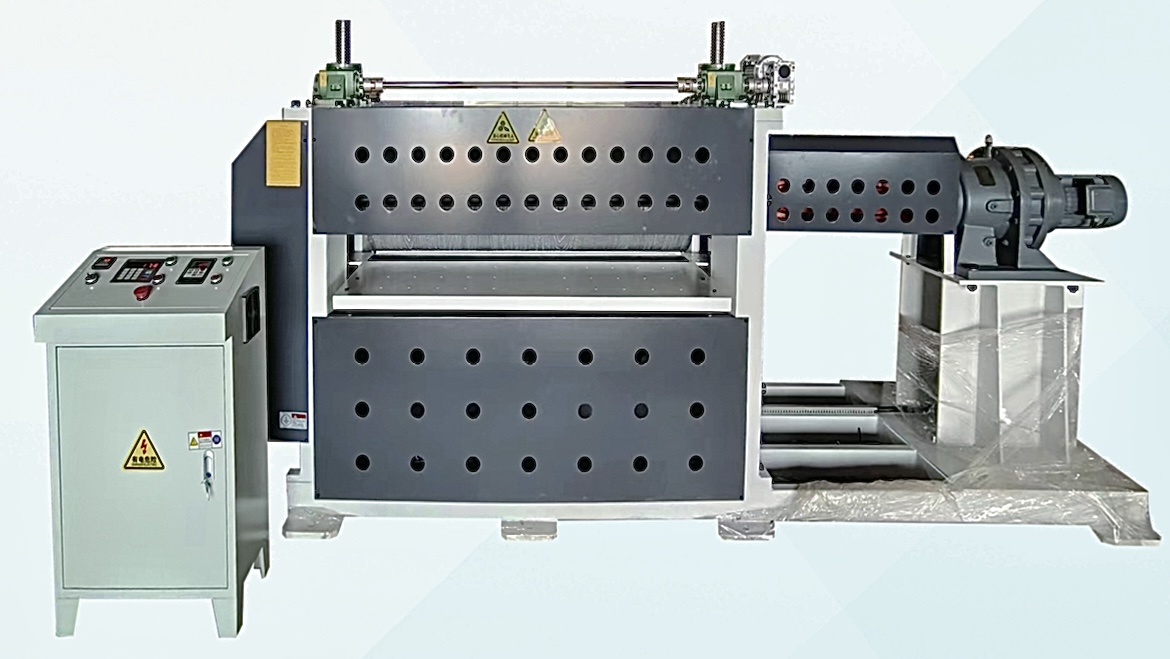

Suitable for solid wood board embossing, plywood embossing, density boards, etc Technical parameters of 1300 embossing machine:

1 The pattern roller is made of high-quality 45 # steel;

2. Wall panel steel structure, heat treated to remove stress;

3.Self aligning roller bearings, equipped with high temperature lubricating grease;

4.Maximum embossing width: 20-1220mm, maximum processing thickness: 2-150mm;

5. The driving power of the embossing roller is 4kw, and the embossing frequency conversion speed regulation is 1~7.5m/min;

6.Specification of pattern roller @320 *1300mm, surface electroplated;

7.The embossing depth is 0.1 ~1.2mm, which can be adjusted at wil.

8. Pattern roller electric heating, heating power 13.2kw, maximum temperature 200 °C, digital display.

9. Machine dimensions: length *width *height=2100 *1200 *1550mm; Weight 2100kg;

In the competitive world of wood products—from luxury furniture to high-end decor—differentiation matters. Meet the Shine Machinery Veneer Embossing Machine: a precision-engineered solution designed to transform plain wood veneer into visually striking, premium-grade materials with unmatched efficiency and versatility. Whether you’re aiming to replicate natural wood grains, create custom textures, or enhance surface durability, this machine redefines what’s possible for your veneer production line.

At the core of our machine lies a 3D servo-controlled pressing system that delivers micro-precision (±0.05mm tolerance) for intricate patterns—from subtle wire-brushed textures to bold geometric designs. Equipped with interchangeable embossing plates (available in 50+ pre-designed motifs or custom options), it ensures consistent, repeatable results across batches, even for thin veneers (0.3-3mm thickness). The result? Veneer that mimics the organic beauty of natural wood or innovates with modern aesthetics, elevating furniture, cabinetry, and wall panels to luxury standards.

Time is money, and our veneer embossing machine optimizes both. With quick-change tooling systems, operators can switch between patterns in under 10 minutes—no lengthy recalibration needed. Paired with a user-friendly touchscreen interface, it allows real-time adjustments to pressure (50-500N/cm²), temperature (60°C-120°C), and speed (0.5-2m/min), adapting seamlessly to different veneer species (oak, maple, walnut, etc.) and project requirements. This flexibility cuts downtime by 40% and ensures you meet tight production deadlines without compromising quality.

Built for industrial rigor, our machine features a robust steel frame, anti-corrosion components, and a sealed pressing chamber to minimize wear from resin or moisture. German-made bearings and Italian hydraulic systems guarantee long-term reliability (MTBF > 50,000 hours), reducing maintenance costs by 30% compared to conventional models. Energy-efficient heating elements and closed-loop cooling further lower operational expenses, making it a cost-effective investment for high-volume producers.

Copyright By © Shandong Shine Machinery Co.,Ltd