In the woodworking industry, achieving smooth, high-quality face veneer is a cornerstone of premium plywood manufacturing. Whether for furniture, flooring, or decorative panels, the drying process directly impacts the final texture, color, and durability of the veneer. Shine Face Veneer Dryers—also known as mesh belt dryers—are engineered to deliver consistent, reliable results, with the mesh belt standing as the unsung hero that defines performance.

The mesh belt is far more than a simple conveyor component in a face veneer dryer—it is the critical link between raw material and finished product. At Shine Machinery, we understand that the quality of the mesh belt directly determines the texture, flatness, and integrity of the dried veneer. That’s why we’ve invested in precision-engineered mesh belts designed to meet the unique demands of thin-face veneer drying.

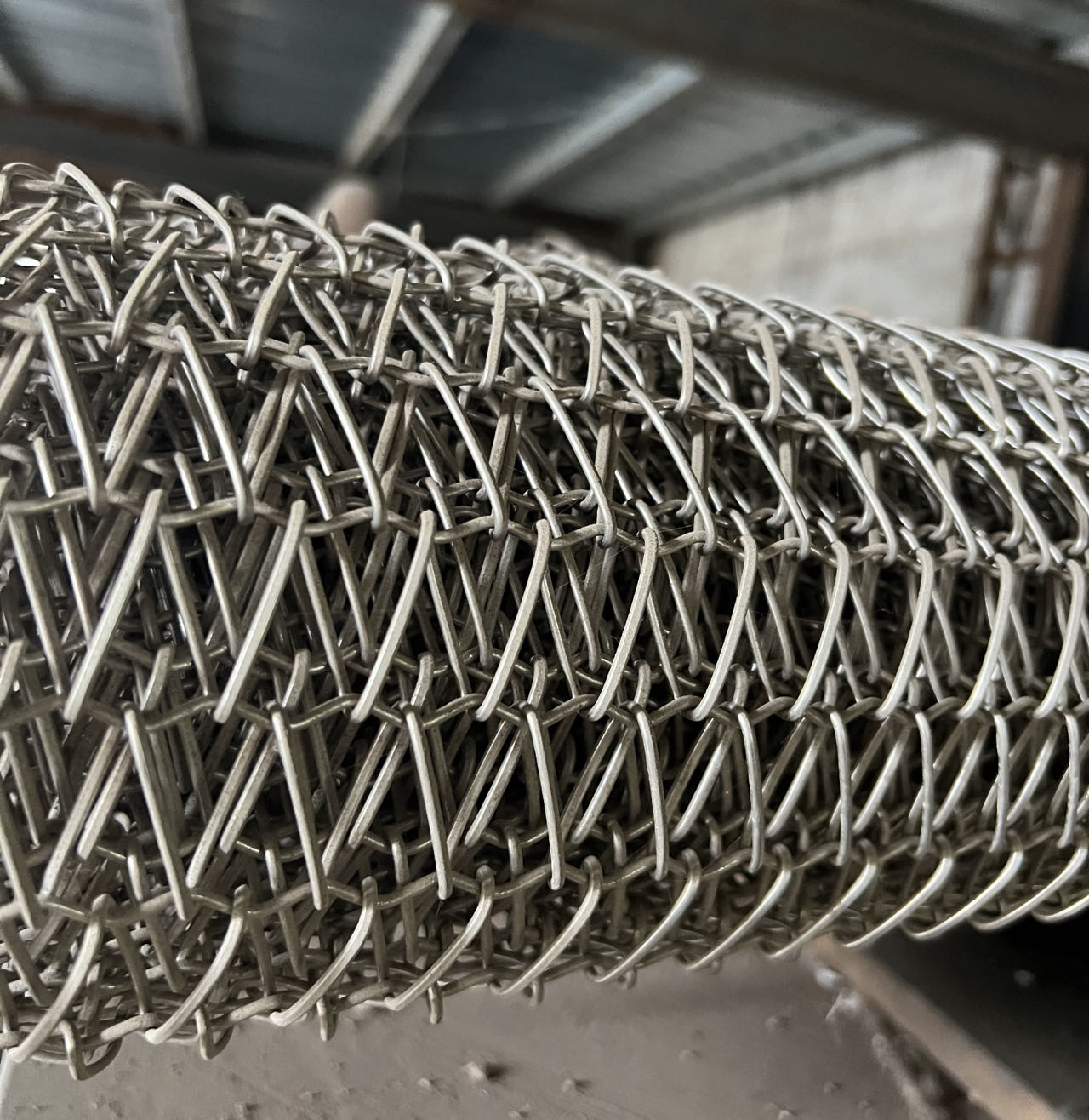

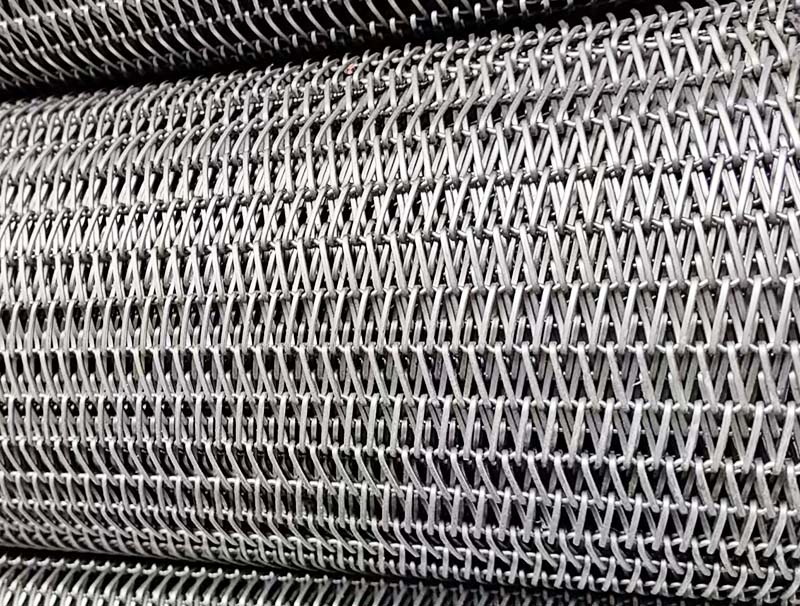

Our mesh belts are crafted from premium stainless steel—available in 201 and 304 grades—to ensure exceptional durability and corrosion resistance. Unlike traditional carbon steel belts, stainless steel resists rust and oxidation, even in high-humidity drying environments, preserving the natural texture of the veneer.

The tight weave and uniform structure of our mesh belts minimize surface friction, preventing scratches or deformation during drying. This ensures the veneer retains its original grain patterns and smoothness, a key requirement for high-end woodworking applications.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd