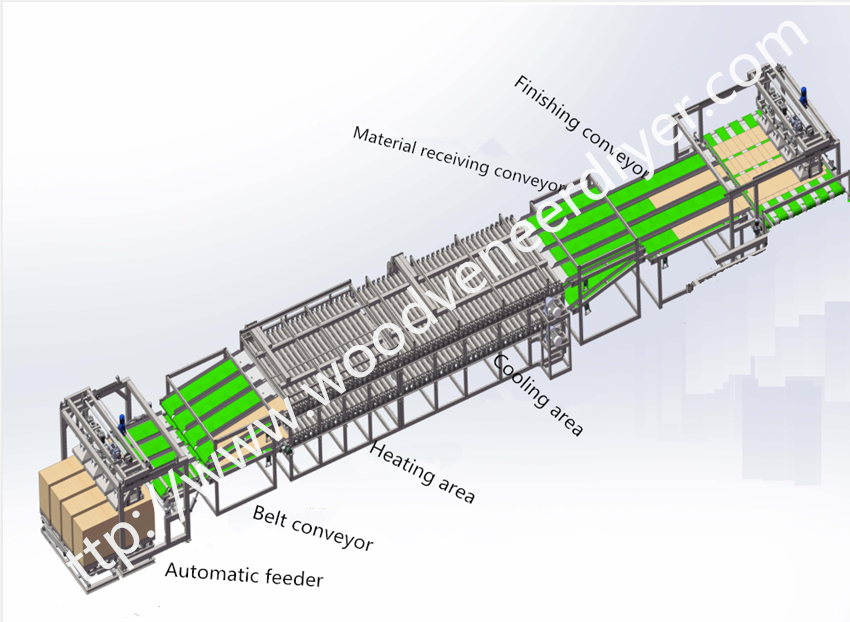

Shine roller core veneer dryer is one kind high efficiency wood plywood drying machine. DHS48M 2deck roller core veneer dryer is a medium size model Shine roller veneer dryer . Shine veneer drying line can be from 20m to 60 m . 1-3 deck. normally 4m is one section. we also can design special ones for different customers' requirements. The main components of Shine environmental plywood dryer equipment is as follows:1.Drying system :the veneer dryer adopts the most scientific drying principle ,and the hot air in the hot air stove is injected directly into the upper and lower bellows of the machine by centrifugal blower. The hot air blows to the upper and lower sides of the running veneer through the nozzles of the upper and lower bellows, so that the veneer is heated evenly and thus plays the role of drying 2.Control system: Adopt endless gearbox to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect. 3.Transmission system :the veneer is fed into the machine through the feed inlet vertically, and the chain drives the upper and lower rows of rollers, running relatively. The veneer moves forward by the self-weight pressure of the upper roll, and during the veneer passes through the two rollers and the upper and lower air nozzles, it achieves the effect of drying and ironing. So the veneer dried by this machine is flat, smooth and without marks. 4.Heating system:Steam heating, heat conduction oil heating, hot stove type heating,waste wood or other biomass materials. Users can choose one most suitable model.

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kw) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

Air cooling fan power(kw) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kw) | 132 | 147 | 158 | 169 | 180 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

Roller Veneer dryer is one of the main equipment in plate production. The quality of veneer drying directly affects the quality of veneer and glued products. The design of hot air continuous roller press is based on the most advanced continuous pressure contact veneer drying technology in the world. The working principle is that the veneer is clamped by the upper and lower seamless steel tube rollers, and the oven temperature reaches 140 ℃ by preheating, and then enters between the upper and lower rollers and lows high pressure hot air to the upper and lower sides of the veneer through the hot air pipe for rapid drying. So it can make the veneer smooth and moisture content even after drying, and it also has the characteristics of direct contact heat transfer between high temperature roller and wet veneer, high thermal efficiency, low heat loss and reducing heat energy consumption.

1. After drying, the veneer is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced.

2. The equipment adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect.

3. The equipment covers a small area, less ancillary equipment, convenient transportation, quick installation, and can be put into use quickly.

4. Each section with heat exchanger, which can make full use of the heat and achieve the best drying effect.

5. All the fans are with converter motor, which can guarantee the service life of the dryer.

Copyright By © Shandong Shine Machinery Co.,Ltd