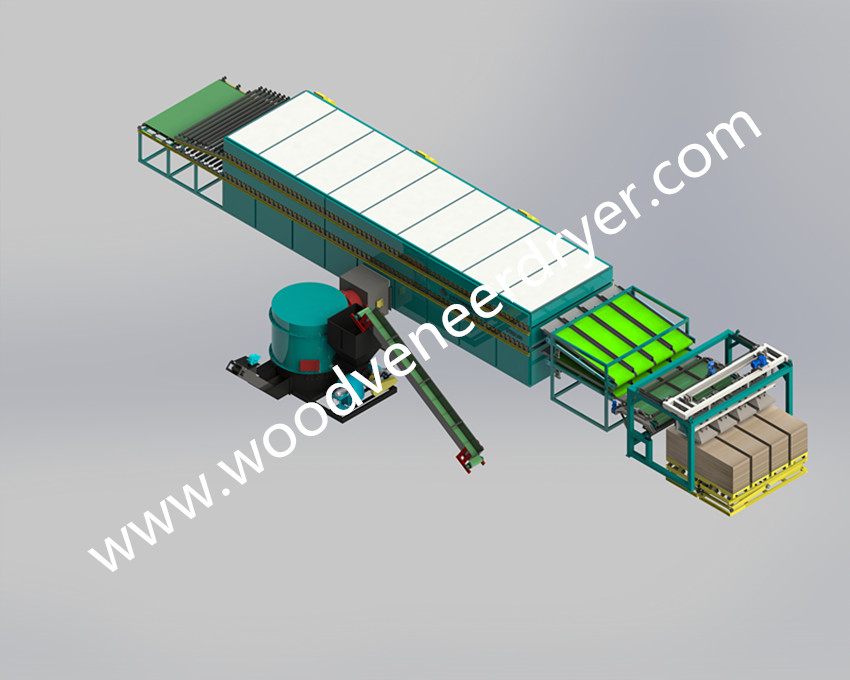

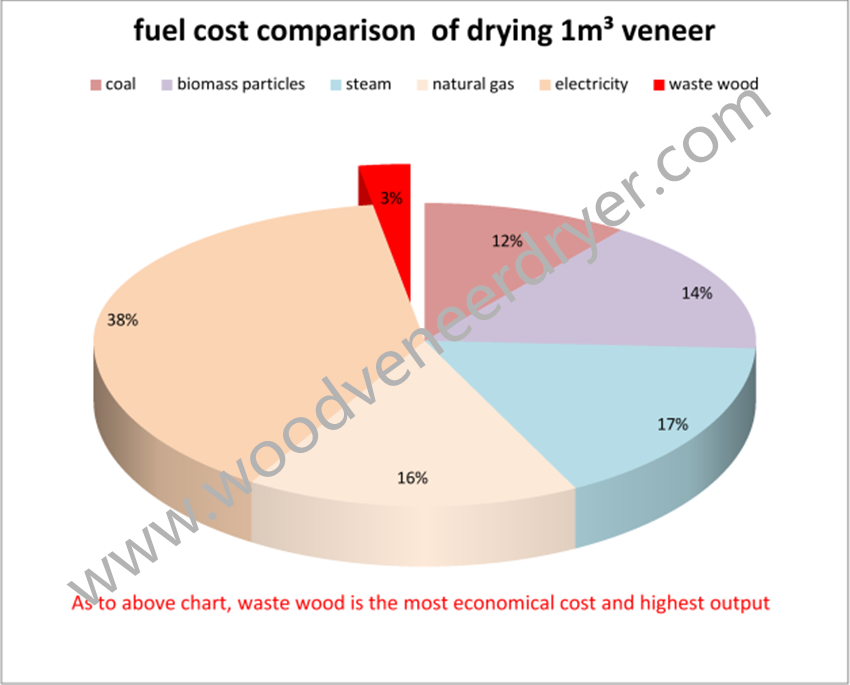

SHINE core veneer dryer machine is one of the most popular woodworking machines . the veneer drying capacity range can be from 15cbm to 150cbm per day. Shine Machinery roller plywood veneer dryer can be designed 1 deck ,2 deck or 3 deck according to different customers' requirements. Normally if the capacity requirement of the roller veneer dryer machine is high . user will choose 2 deck or 3 deck veneer dryer . The main advantages of the 2 deck roller veneer drying machine is that it can save areas and improve working capacity.The veneer dryer produced by Shandong Shine Machinery Co., Ltd. is widely used in flatting drying of high-grade plywood, multi layer board and architectural core face veneer.It is equipped with environmental protection type hot air stove. its characteristics: save fuel, twice use of hot air , increase heating speed.the veneer after drying is flat,moisture content is up to national standard. Equipped with integral type high efficiency energy saving hot air stove. No boiler and other auxiliary equipment, no use water,coal, electricity. Rind ,wood chips and wood craps are all can be as fuel. and can quickly achieve the heat required by the dryer.

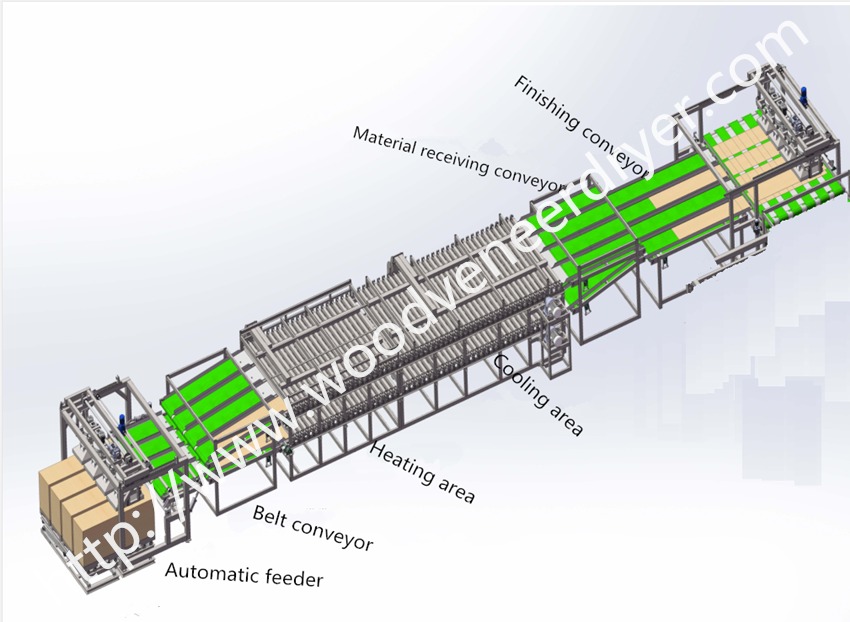

Roller veneer dryer machine is one of the main equipment in plate production. The quality of veneer drying directly affects the quality of veneer and glued products. The design of hot air continuous roller press is based on the most advanced continuous pressure contact veneer drying technology in the world. The working principle is that the veneer is clamped by the upper and lower seamless steel tube rollers, and the oven temperature reaches 140 ℃ by preheating, and then enters between the upper and lower rollers and blows high pressure hot air to the upper and lower sides of the veneer through the hot air pipe for rapid drying. So it can make the veneer smooth and moisture content even after drying, and it also has the characteristics of direct contact heat transfer between high temperature roller and wet veneer, high thermal efficiency, low heat loss and reducing heat energy consumption.

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kw) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

Air cooling fan power(kw) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kw) | 132 | 147 | 158 | 169 | 180 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd