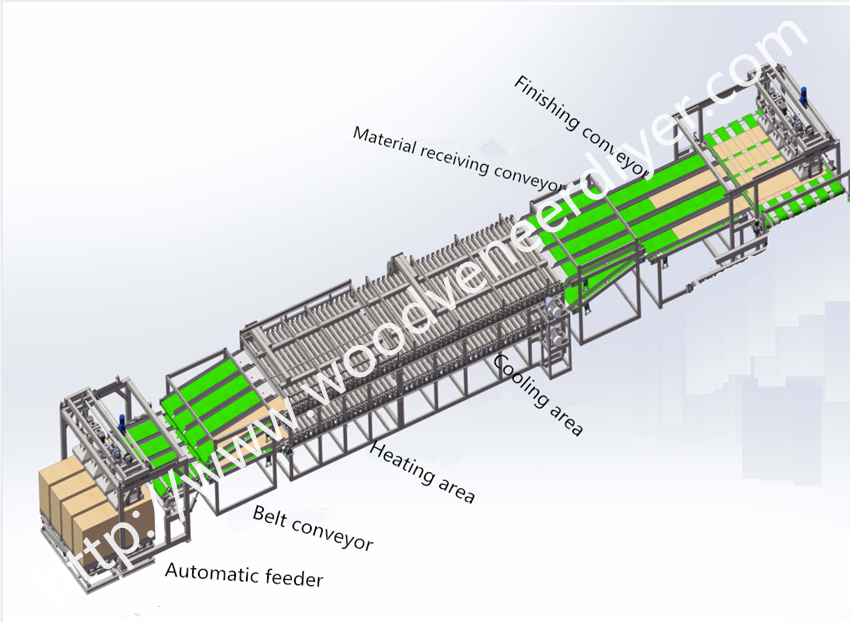

48m 2 deck timber heat conduction oil roller veneer dryer is one of Shine normal roller veneer dryers. The capacity of DHS48M veneer drying machine is about 80cbm per day . Also Shine machinery can make other capacity roller veneer drying machine according to customers requirements . It can be 20-60m and 1-3 deck,also we can design special models according to customer's special requirements.The plywood veneer dryer produced by Shandong Shine Machinery Co., Ltd. is widely used in flatting drying of high-grade plywood, multi layer board and architectural core face veneer. Shine roller veneer drying equipment is equipped with environmental protection type hot air stove. its characteristics: save fuel, twice use of hot air , increase heating speed.the veneer after drying is flat,moisture content is up to national standard. Except for heat conduction oil heating source , Shine Machinery can also do electricity heating , built-in furnace roller vneer dryer ,natural gas heating models, biomass furnace type roller veneer dryer. users can choose the most suitable heating type according to material cost .

Parameter Model |

DHS44M

| DHS48M | DHS52M | DHS56M | DHS60M |

Work width(m) | 3 | 3 | 3 | 3 | 3 |

Layer | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 40 | 44 | 44 | 48 | 52 |

Cooling area (m) | 4 | 4 | 4+4 | 4+4 | 4+4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 2.7-3.1 | 3-3.3 | 3.2-3.5 | 3.5-3.8 | 3.8-4.1 |

Heat exhaustion(10000 kcal) | 94.5-108.5 | 105-115.5 | 112-122.5 | 122-132 | 132-143 |

Traction motor power(kw) | 5.5*2 | 7.5*2 | 7.5*2 | 7.5*2 | 7.5*2 |

Hot air fan power (kw) | 11*10 | 11*11 | 11*11 | 11*12 | 11*13 |

Air cooling fan power(kw) | 11 | 11 | 11*2 | 11*2 | 11*2 |

Total power (kw) | 132 | 147 | 158 | 169 | 180 |

Overall size LxWxH(m) | 44*4.5 | 48*4.5 | 52*4.5 | 56*4.5 | 60*4.5 |

1. The veneer after drying by Shine veneer dryer machine is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect.

3.Shine roller plywood veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements.which can meet different customers' requirements.

Copyright By © Shandong Shine Machinery Co.,Ltd