Factors that affect the drying of veneer in include both the wood itself and the drying conditions.

An obvious factor is the thickness of the veneer. Thicker veneers dry more slowly than thin veneers. A modification of this is variation in veneer thickness from the nominal thickness. Commercial 1/8-inch (3.2-mm.) veneer will often vary ±0.008 inch (0.2 mm.) or more in thickness. The thicker portions of the veneer take longer to dry than the thinner portions and contribute to nonuniform final moisture content.

A second factor is the grain direction on the surface of the veneer. End grain dries several times faster than tangential (flat) grain. End-grain drying is significant at the ends of all veneer sheets, which tend to dry faster than the bulk of the sheet. It may also be a factor in curly grained or other figured veneer where at least partial end grain is exposed on the broad surface of the veneer. As these areas dry faster than surrounding straight-grain areas, they can cause stresses and buckling in the veneer sheet. The difference in drying rates between radial and tangential surfaces is small but may show up in that quarter-sliced veneer will take slightly longer to dry than rotary-cut veneer of the same thickness and flat-sliced veneer may dry slower on the near-quarter edges than in the flat-grain area at the center of the sheet.

The moisture in the veneer affects the total drying time. The moisture content of butt logs may be higher than the moisture content of top logs. For example, the difference in moisture content of the heartwood of redwood from different logs may be as much as 2 to 1. The wetter heartwood veneer requires significantly longer drying time than drier heartwood of the same species.

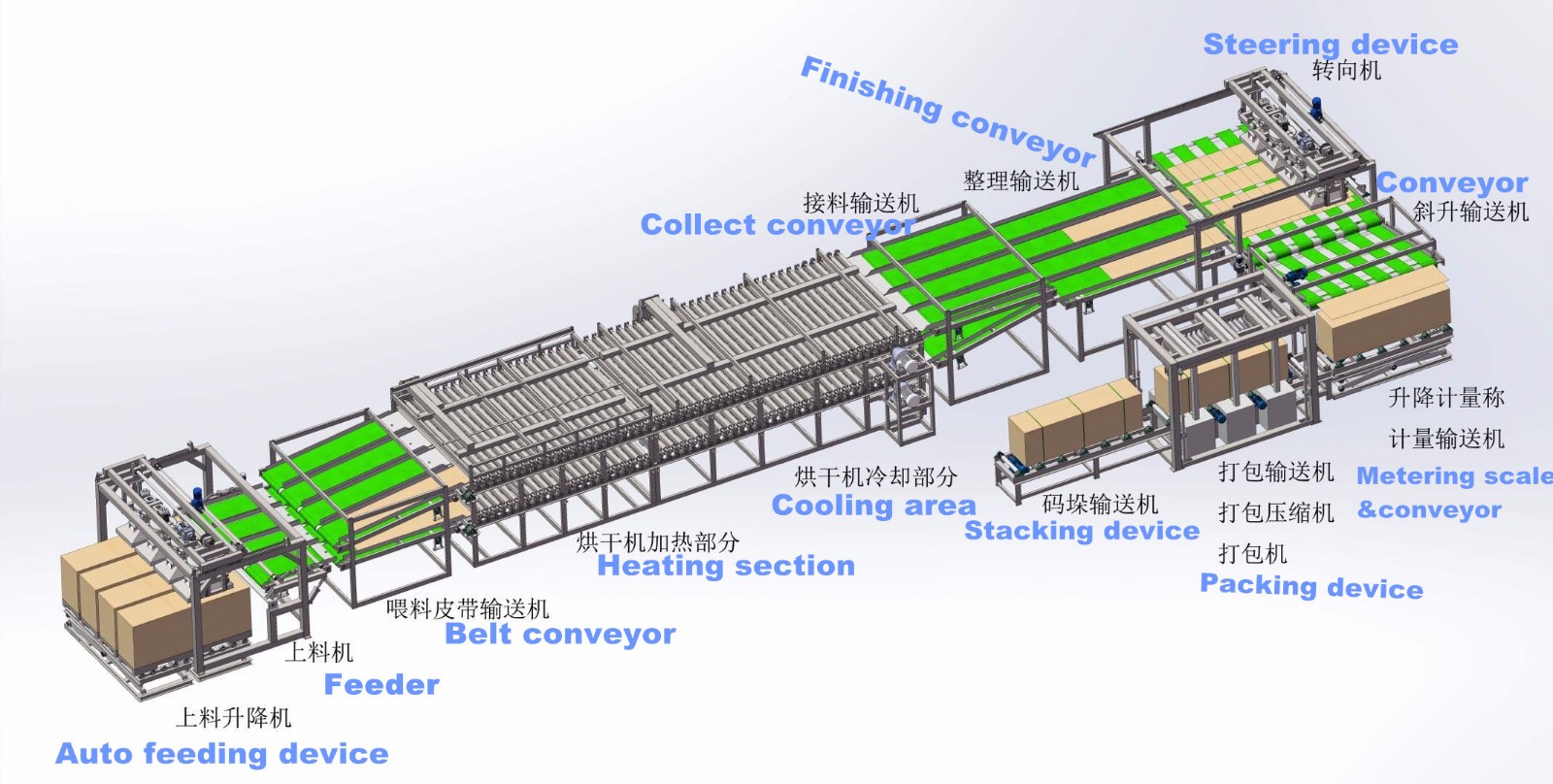

Main Technical Parameter for Factors that Affect the Drying of Veneer

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 2 | 2 | 2 | 2 | 2 | 2 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 0.8-1.1 | 1.1-1.4 | 1.5-1.8 | 1.8-2.2 | 2-2.5 | 2.4-2.7 |

Heat exhaustion(10000 kcal) | 28-38.5 | 38.5-49 | 52.5-63 | 63-77 | 70-87.5 | 84-94.5 |

Traction motor power(kw) | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 | 5.5*2 |

Hot air fan power (kw) | 11*4 | 11*5 | 11*6 | 11*7 | 11*8 | 11*9 |

Air cooling fan power(kw) | 11 | 11 | 11 | 11 | 11 | 11 |

Total power (kw) | 66 | 77 | 88 | 99 | 110 | 121 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

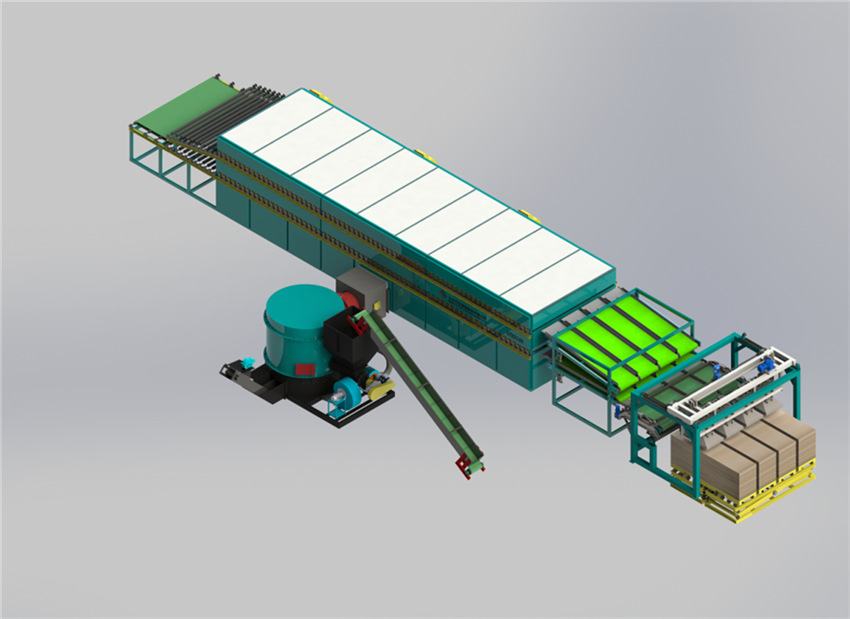

Jet Roller Veneer Dryer Packing and Shipment

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd