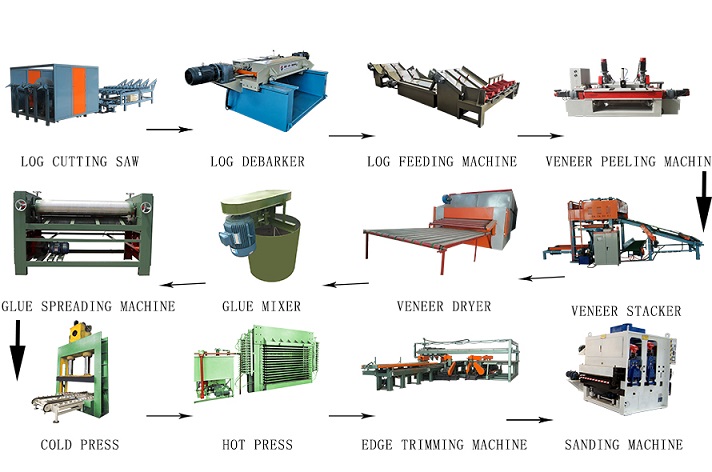

The process flow of log processing and production of plywood: log-→ log sawing → wood section cooking → wood section peeling → veneer peeling → veneer drying → veneer finishing → gluing and assembly → cold pressing + hot pressing → trimming → Sanding → inspection and grading → packaging and storage.

The process flow of veneer processing and production of plywood: veneer finishing → gluing and assembly → pre-pressing-→ hot pressing → cutting → sanding → inspection and grading → packaging and storage.

Processing loss: In the entire production process of plywood, log sawing, veneer peeling, veneer drying, veneer finishing, hot pressing, trimming and sanding have an impact on wood loss. It is divided into tangible loss (with remaining processing) Material) and intangible loss (shrinkage and compressed wood loss are related to the raw wood species, log specifications, equipment conditions, process technology, and finished board specifications.

Log sawing: The length of imported logs should be sawed according to the length and quality required by the process. At this time, a wood-breaking saw is needed. The intercepted wood section should be the total length of the finished plywood and the length of the processing allowance. For example, the finished plywood with a format of 1220mmX2440mm, the length of the wood section is usually 2600mm or 1300mm. The length of the log and the curvature and defects of the log directly affect the yield of the plywood. The waste generated includes small wood segments, truncated ends and sawdust, and the log sawing loss rate is generally 10%.

Veneer peeling: The most widely used plywood production is to produce veneer by rotary veneer peeling machine. The thickness of the face and back board is generally about 0.6m, and the thickness of the core board and the long and medium board is generally about 8mm. This process has the largest loss. One is due to the out-of-roundness of the wood section, and a considerable part of the broken veneer cannot be used; the other is the end loss caused by the clamping of the rotary cutter chuck on both ends of the wood section; the third is the loss of the wood core. The waste generated by the peeling of the veneer is the shredded veneer and the wood core. It can be seen that the loss of the veneer is related to the material, diameter and equipment performance of the wood section.

Veneer drying: The moisture content of the veneer after peeling is very high, and the veneer must be dried to meet the requirements of the gluing process. The size of the wood becomes smaller after drying through the dryer, which is called shrinkage. As the moisture content decreases, the length, width and thickness of the veneer will shrink. The drying shrinkage loss is related to the tree species of the veneer, the moisture content of the veneer, and the thickness of the veneer. The shrinkage loss rate is generally 1%~10%.

Veneer finishing: Veneer finishing includes cutting, splicing and repairing. Cut the dried strip veneers and single veneers into specification veneers and splicable veneers. The narrow veneers are spliced into a whole veneer, and the entire defective veneer can be repaired to achieve the process Quality requirements. The amount of waste veneer produced in this process is related to factors such as the log material, the quality of the peeled veneer, the quality of the dry veneer, and the familiarity of the operators with the veneer standard. The loss rate is generally 4% to 16%. The loss rate of the process of directly importing veneer into plywood is generally 2%~11%.

Hot pressing: The slabs that have been glued and assembled are firmly glued together through a certain temperature and a certain pressure. As the temperature and moisture content of the slab change during hot pressing, the wood is gradually compressed and the thickness of the slab gradually decreases. This loss is compression loss, which is related to the hot pressing temperature, unit pressure, hot pressing time, tree species and moisture content of the plywood. The loss rate is generally 3% to 8%.

Trimming: Cut the hot-pressed rough board into specifications. The amount of scraps cut off is related to the processing allowance and format size of the plywood. The larger the plywood format, the smaller the trimming loss rate, which is generally 6%-9%.

Sanding: Sanding the surface of the plywood to make the surface smooth and beautiful. The waste produced in this process is sanding powder. When the quality of the veneer is good, the amount of sanding is small, and the sanding loss rate is generally 2% to 6%.

In the case of normal materials, the loss rate of log processing and production of plywood is generally 7% to 55%, and the loss rate of directly imported semi-finished veneer processing and production of plywood is generally 6 to 26%.

Copyright By © Shandong Shine Machinery Co.,Ltd