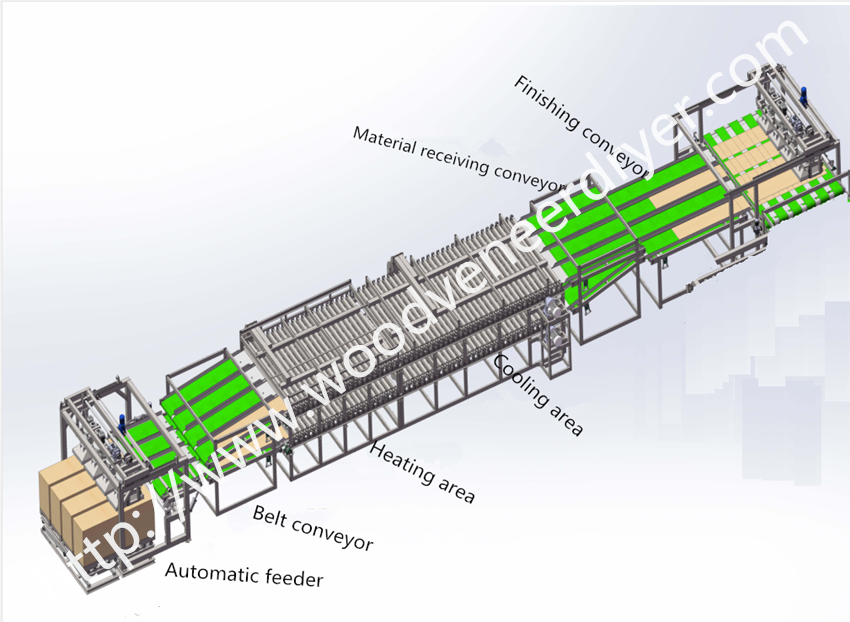

3 Deck roller veneer dryer machine is one of Shine roller type timber veneer drying machine. it utilizes the latest international technology of pressurized contact veneer drying, which has the advantages of simple operation, safety and practicality, stable operation, easy maintenance, hot-pressing-levelling--drying once completed, etc. The use of hot air circulation has greatly reduced the operating costs of enterprises, improved the quality of sheet materials and increased the production volume. The roller plays a role in ironing the veneer. After the veneer is dried by Shine roller veneer dryer machine , the veneer is flat and the moisture content is relatively uniform. When the veneer is located between two roller sets, the lateral direction can be freely contracted, the occurrence of cracks is reduced, and the drying quality is good. The heat dissipation process is carried out in a flat state. In the benign physical process of wood shrinkage, the veneers do not warp and deform, the breakage rate is low, and the yield rate is high. Roller core veneer dryer machine is popular in Southeast Asia areas. we also can do other type veneer dryer such as electricity veneer dryer , coal veneer dryer,Gas-fired integrated veneer dryer. and biomass veneer dryer, which is the most economic ones to use biomass as heat source.

Parameter Model |

DHS20M

| DHS24M | DHS28M | DHS32M | DHS36M | DHS40M |

Work width(m) | 3 | 3 | 3 | 3 | 3 | 3 |

Deck | 3 | 3 | 3 | 3 | 3 | 3 |

Veneer thickness(mm) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

Heating area (m)

| 16 | 20 | 24 | 28 | 32 | 36 |

Cooling area (m) | 4 | 4 | 4 | 4 | 4 | 4 |

Initial water content(%) | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

Finished water content(%) | 10 | 10 | 10 | 10 | 10 | 10 |

Drying capacity (m³/h) | 1.3-1.67 | 1.67-2.05 | 2.05-2.55 | 2.55-3.06 | 2.93-2.45 | 3.32-3.83 |

Heat exhaustion(10000 kcal) | 44-58 | 57-72 | 70-88 | 88-105 | 100-118 | 114-132 |

Total power (kw) | 100 | 116 | 128 | 144 | 160 | 177 |

Overall size LxWxH(m) | 20*4.5 | 24*4.5 | 28*4.5 | 32*4.5 | 36*4.5 | 40*4.5 |

1. The veneer after drying by Shine veneer dryer machine is smooth and the moisture content is uniform, and the high temperature drum has direct contact with the wet veneer for heat transfer, and the heat efficiency is high, the heat loss is small, and the heat loss is reduced. the selling price for veneer dried by roller veneer dryer is higher than natural drying.

2.The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve ideal drying effect.

3.Shine roller veneer dryer covers a small area, less ancillary equipment, convenient for transportation, quick installation, and can be put into use quickly and conveniently.

4.Standardized production models, can make different sections or decks according to different capacity requirements.which can meet different customers' requirements.

RELATED

RELATED

Copyright By © Shandong Shine Machinery Co.,Ltd